Case Study: Chemical Hazard Animation Safety Video

Introduction: Chemical Hazard Animation Video

Let’s get started with the Chemical Hazard Animation Video Case Study. Here, we will take you on a detailed and engaging 3D explainer video about industrial chemical safety, the use of industrial safety equipment, and how we simplified complex safety information, improved hazard identification, and boosted workplace safety compliance.

Client Video: Chemical Hazard Animation Video

Highlights: Chemical Hazard Animation Video

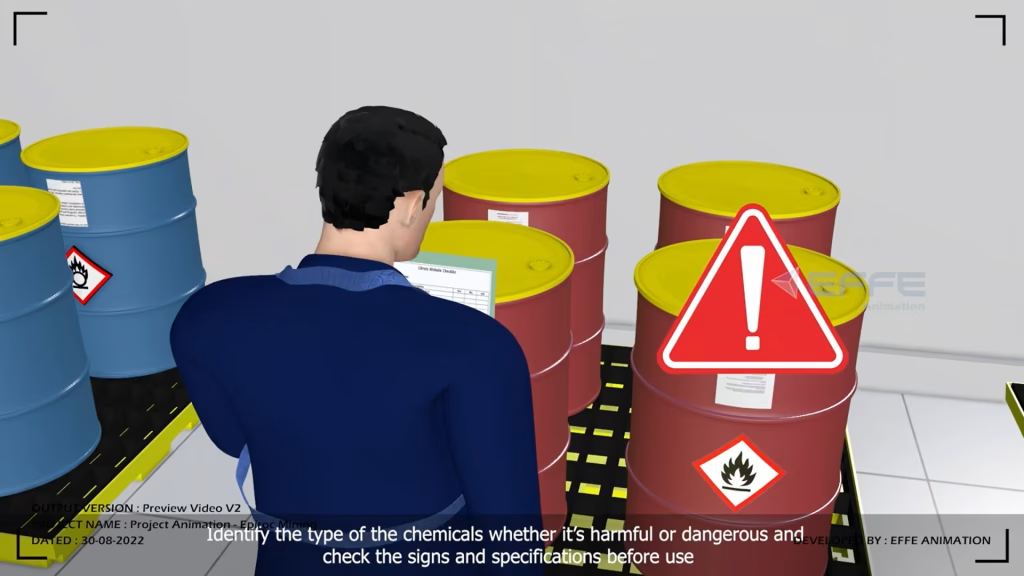

1. Identification of chemical hazards before use is mandatory.

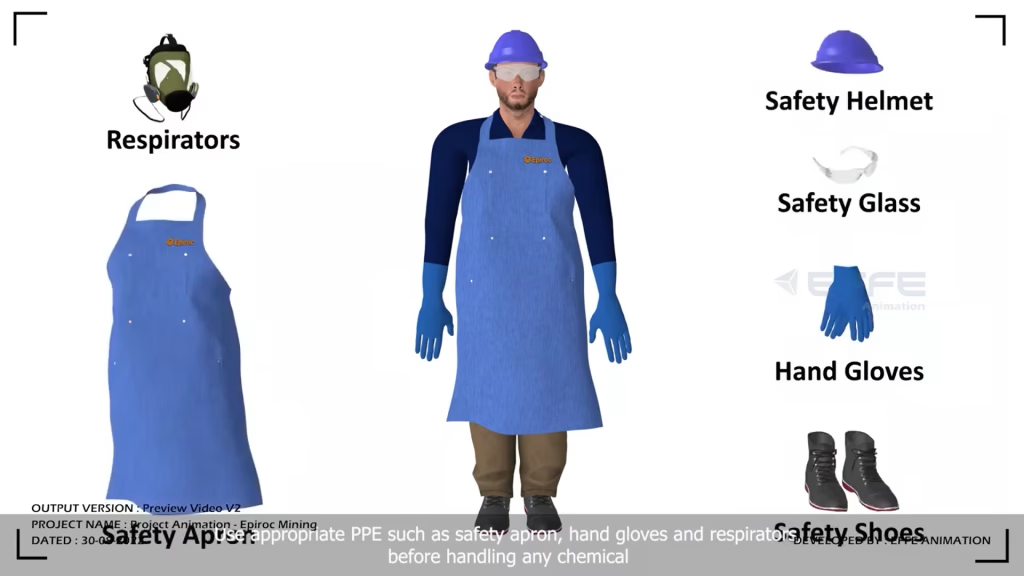

2. Use of appropriate PPE such as gloves, aprons, respirators, and face shields is crucial.

3. Hazard identification and risk assessment must precede chemical handling.

4. Proper labeling and storage of chemicals prevent accidents and environmental damage.

5. No eating, drinking, or smoking is allowed when handling chemicals.

6. Immediate first aid and reporting systems are in place for chemical exposure incidents.

7. Maintaining and consulting Material Safety Data Sheets (MSDS) is essential.

Key Insights: Chemical Hazard Animation Video

Comprehensive Chemical Hazard Awareness:

The requirement to identify chemical types and understand their hazardous nature before use helps prevent accidental exposure and ensures that workers are adequately prepared. This proactive approach is vital in mining environments where multiple hazardous chemicals are in use.

PPE as a Critical Barrier:

The emphasis on PPE, tailored to specific chemicals such as liquid nitrogen requiring face shields and full body aprons, underscores the importance of matching protective measures to the chemical risk to minimize skin contact, inhalation, and ingestion.

Hazard Identification and Risk Assessment as Standard Practice:

Conducting thorough pre-use assessments means that risks can be anticipated and mitigated early on, reducing the likelihood of accidents and ensuring that all who handle chemicals are aware of potential dangers.

Effective Chemical Storage and Labeling:

Classifying chemicals with clear labels (explosive, flammable, oxidizing, corrosive, toxic) and storing them in ventilated, secure areas using color-coded or secondary containment strategies addresses risks of chemical reactions, fires, and environmental contamination, showcasing sound risk management.

Behavioral Controls Prevent Contamination:

Banning eating, drinking, or smoking during chemical handling reduces the risk of ingestion-related health hazards and promotes discipline and hygiene in hazardous zones.

Robust Emergency Preparedness:

Immediate reporting and access to trained first aiders and supervisors ensure prompt response to exposure incidents, potentially saving lives and minimizing injury severity. This reflects strong organizational commitment to worker welfare.

MSDS as an Information Cornerstone:

Maintaining detailed MSDS for all chemicals—covering physical and chemical characteristics, fire hazards, handling protocols, and emergency instructions—serves as an indispensable reference, enhancing knowledge transfer and preparedness among employees, thus reinforcing safety culture.

Summary: Chemical Hazard Animation Video

Credit: Chasing Illusions

Epiro Mining India Limited upholds strict safety protocols to ensure the safe and efficient handling of the numerous chemicals used in its daily operations. The animation video emphasizes the importance of correctly identifying each chemical type and its potential hazards before use, including understanding hazard signs and material specifications. It further highlights the proper use of personal protective equipment (PPE)—such as gloves, aprons, respirators, and face shields—which is essential for minimizing risks. Special attention is given to handling high-risk substances like liquid nitrogen, reinforcing the need for strict compliance with safety measures.

Before any chemical is used, thorough hazard identification and risk assessments must be carried out to ensure workplace safety. The video also outlines best practices for safe chemical storage, including clear labeling of substances as explosive, flammable, oxidizing, corrosive, or environmentally hazardous. It highlights the importance of keeping chemicals in well-ventilated areas, using color-coded containers for flammable materials, and applying secondary containment measures for high-risk substances such as diesel and paint.

The handling protocols emphasize the importance of avoiding inhalation, ingestion, and direct skin contact with chemicals, while strictly prohibiting eating, drinking, or smoking in areas where hazardous materials are present. The video also reinforces the need for immediate reporting of incidents and following proper first aid response procedures in the event of chemical exposure.

Environmental safety measures focus on preventing chemical leaks from entering rainwater drains and ensuring all spills are cleaned up promptly. The protocols also mandate maintaining and regularly referencing Material Safety Data Sheets (MSDS) for every chemical, providing detailed information on each substance’s properties, safe handling procedures, and appropriate emergency response actions.

The collective adherence to these safety rules aims to foster a hazard-free work environment driven by innovation and united performance at Epiro Mining India Limited.

Client Overview:

Name: Epiroc Mining India Limited

Industry: Mining and Infrastructure

About: Epiroc, established in 1949, is a leading productivity partner for the mining, infrastructure, and natural resources industries. Using advanced technology, Epiroc develops and manufactures innovative drill rigs, rock excavation, and construction equipment, while also delivering world-class service and consumables.

Why Choose Us:

Epiroc Mining India Limited selected Chasing Illusions Studio as their trusted partner for developing a 3D chemical hazard safety animation video, recognizing us as the best 3D explainer video company for industrial safety training. Our expertise lies in transforming complex industrial protocols into clear, engaging, and visually accurate 3D animations that enhance safety awareness and compliance. Impressed by the effectiveness of our past projects with leading industrial clients, Epiroc confidently chose Chasing Illusions to bring their industrial chemical safety training video to life.

In this context, the 3d animation video is about how to identify the chemical type and associated hazards before use, including recognizing signs and specifications, and also the use of safety kits at the workplace.

Our 3D safety animations clearly demonstrate potential risks, safe handling practices, and emergency response measures in a way that is both easy to understand and highly memorable. By combining realism, compliance-driven accuracy, and training effectiveness, we enable industries to strengthen workplace safety, enhance hazard awareness, and achieve better compliance through powerful visual storytelling.

Client Challenge:

Before the adoption of technology and 3D animation, industries primarily depended on traditional safety manuals, static diagrams, and in-person demonstrations to educate employees about chemical hazards. This conventional approach was time-consuming, inconsistent, and prone to misinterpretation, leaving critical gaps in training. Without visual clarity or scenario-based learning, employees often struggled to fully understand the seriousness of potential risks—resulting in higher accident rates, slower emergency responses, and significant safety shortcomings on the shop floor.

Industries aiming to modernize their training programs are increasingly turning to advanced technology and the best animation production companies to create chemical identification and industrial safety equipment animation videos. However, this transition comes with challenges—such as accurately visualizing complex chemical reactions, ensuring strict compliance with safety regulations, and presenting highly technical procedures in a way that is clear, engaging, and accessible to workers at all levels.

Faced with this challenge, Epiroc aimed to simplify complex safety concepts and effectively educate industry employees, partner companies, and the mining & infrastructure sectors about chemical-related hazards. The focus was on identifying hazard signs and specifications before chemical use, while also reinforcing the correct usage of industrial safety equipment to ensure maximum workplace protection.

Our Process:

Our process began with an initial discussion to understand the specific chemical hazards and safety protocols, risk factors involved in the industrial environment.

Next, our team developed the clear visual concepts for demonstrating these hazards, including the potential dangers, correct handling procedures, and use of PPE kit properly, using accurate 3D models and animation that reflect real-life scenarios.

Now, the animation focuses on visually depicting the risks and proper safety measures in an engaging and easy-to-understand manner. Finally, we’d add concise voiceovers and on-screen text to reinforce the safety messages, ensuring the video effectively educates and trains industrial workers on chemical safety.

The goal is to create a video that not only educates but also reinforces safe practices in a way that’s memorable, practical, and aligned with industry standards.

Solution: Chemical Hazard Animation Video

Meeting Epiroc’s requirements, we produced a 3-minute 3D animation video that demonstrates how to identify chemical types and their associated hazards before use. The video also guides viewers on recognizing hazard signs and specifications and provides clear instructions on the proper use of industrial safety PPE kits.

We developed a solution that turned complex chemical safety protocols into a visually engaging and easy-to-understand 3D animation. By clearly depicting hazardous scenarios, correct handling procedures, and emergency response measures, the video effectively enhances safety training and awareness across all employee levels.

By using clear visual metaphors, step-by-step demonstrations, and concise narration, our 3D safety videos make critical safety messages easy to understand and remember. Compared to traditional manuals or static presentations, this approach significantly enhances comprehension and retention, helping industrial workers internalize best practices. As a result, it directly contributes to a safer workplace by proactively educating employees and reinforcing proper safety protocols.

Results: Chemical Hazard Animation Video

Epiroc’s decision to trust in Chasing Illusions for Industrial Safety with Chemical Hazard Animation Video brought significant results:

Improved Safety Protocol Comprehension

The final 3D animation simplified complex chemical safety protocols into clear, easily digestible visual steps. By vividly demonstrating handling procedures, proper use of personal protective equipment (PPE), and emergency responses to chemical spills or exposures, the video greatly improved workers’ understanding and retention of critical safety information. This led to stronger adherence to safety regulations and safer practices across industrial settings throughout India.

Reduced Incidents and Accidents

By effectively communicating safety procedures and the consequences of non-compliance, the animation directly helps reduce chemical-related incidents and accidents. When employees clearly understand potential risks and how to mitigate them, errors are minimized, creating a safer workplace and reducing the likelihood of injuries or costly damages.

Increased Awareness of Chemical Risks

Using vivid and precise animated scenarios, the video clearly illustrated the potential dangers of workplace chemical hazards. By visually showing the consequences of improper handling or accidents, it made risks more tangible and memorable for employees. This heightened awareness helps foster a proactive safety culture and encourages cautious, safety-first behavior among industrial workers.

Enhanced Training Effectiveness and Engagement

The dynamic and engaging nature of animated content, compared to static presentations or lengthy manuals, makes safety training significantly more effective and captivating. Employees are more likely to focus on and retain information when it is presented through interactive visuals and clear narration. This approach not only streamlines the training process but also ensures workers are better prepared to handle hazardous materials safely, particularly in industrial settings.

Compliance Support and Professional Image

The high-quality, professional 3D animation serves as an effective tool to demonstrate a company’s commitment to industrial safety and regulatory compliance. It can be utilized during safety audits, new employee onboarding, and ongoing training programs, highlighting a proactive approach to worker well-being. Beyond meeting legal and ethical obligations, the animation also enhances the company’s reputation as a responsible and safety-conscious employer.

Conclusion: Chemical Hazard Animation Video

Chasing Illusions’ “Enhancing Industrial Safety with Chemical Hazard Animation Video” successfully bridges the gap between technical safety guidelines and practical employee understanding. By combining realistic visuals, clear messaging, and scenario-based learning, we’ve created a powerful tool that improves safety awareness, reduces training time, and minimizes workplace risks. The final video served as a long-term asset for industries aiming to elevate their safety standards and foster a proactive safety culture through effective visual communication.

Learn More About OSHA Safety Training

FAQs: Chemical Hazard Animation Video

How can a chemical hazard animation video improve workplace safety?

A chemical hazard animation video visually illustrates safe handling practices, emergency procedures, and potential risks, making safety protocols clearer and easier to remember. It enables workers to grasp complex information quickly, minimizes human error, and promotes consistent safety practices across all departments.

Can the video be used for ongoing training and compliance audits?

Absolutely. The animation is designed for multi-purpose use, including employee onboarding, refresher training, and regulatory audits. It acts as a long-term safety resource, helping teams stay aligned with best practices and compliant with evolving safety standards.

Which is the best Industrial Animation services Company?

Chasing Illusions Studio is recognized as the best industrial animation services company in India, specializing in transforming complex industrial protocols into clear, engaging, and visually precise 3D videos. By combining technical accuracy with creative storytelling, we deliver impactful content for the manufacturing, engineering, and infrastructure sectors. From product walkthroughs to safety and training animations, we bring industrial concepts to life with clarity, engagement, and measurable impact.

How to contact Chasing Illusions Studio for 3D Industrial Animation video Projects?

You can contact Chasing Illusions in different ways, like: official website- chasingillusions.com, call or message on WhatsApp, or even get your customized industrial animation quote by filling “Get Quote Form”

CONTACT NOW

Hurry Up!!! Your Customized 3D Industrial Animation video is a Step Away!