How UAE Refineries Use Hydrogen Sulfide Safety Training Videos to Protect Workers

The United Arab Emirates (UAE) is a cornerstone of the global oil and gas industry, with its refineries, such as those operated by the Abu Dhabi National Oil Company (ADNOC), processing vast quantities of crude oil and natural gas. However, these operations face significant risks from hydrogen sulfide (H₂S), a toxic and flammable gas known as the “silent killer.” To mitigate these dangers, UAE refineries rely on hydrogen sulfide safety training videos to educate workers, ensure compliance with strict safety regulations, and foster a culture of safety. This comprehensive guide explores how hydrogen sulfide safety training videos are used in UAE refineries to protect workers, detailing their applications, benefits, and creation process, while aligning with ADNOC’s Health, Safety, and Environment (HSE) standards and international guidelines like OSHA and NFPA.

Understanding Hydrogen Sulfide Hazards in UAE Refineries

What is Hydrogen Sulfide (H₂S)?

Hydrogen sulfide is a colorless, highly toxic gas with a characteristic “rotten egg” odor at low concentrations. In UAE refineries, H₂S is a common byproduct during crude oil refining, gas processing, and maintenance activities. Hydrogen sulfide safety training videos are critical for raising awareness about its dangers.

Key Characteristics:

-

Toxicity: Exposure to 100 ppm can cause loss of smell, while concentrations above 700 ppm can lead to unconsciousness or death within minutes.

-

Flammability: H₂S is highly flammable, with a lower explosive limit of 4.3%, posing fire and explosion risks.

-

Odor Detection: Detectable at 0.0005–0.3 ppm, but olfactory fatigue at higher levels makes it undetectable by smell, necessitating robust monitoring systems.

H₂S Risks in UAE Refineries

UAE refineries, such as ADNOC’s Ruwais and Habshan facilities, encounter H₂S in:

-

Crude Oil Processing: H₂S is released during desulfurization or distillation.

-

Gas Treatment: Sour gas processing plants remove H₂S from natural gas streams.

-

Maintenance Operations: Pipeline or equipment repairs can release trapped H₂S.

Health Effects:

-

Low Exposure (1–10 ppm): Eye irritation, headaches, nausea.

-

Moderate Exposure (50–100 ppm): Dizziness, respiratory distress, loss of smell.

-

High Exposure (500+ ppm): Rapid unconsciousness, coma, or death.

Incident Risks: Globally, H₂S causes numerous fatalities in oil and gas operations. A 2019 incident in Texas highlighted the dangers when a worker and his wife succumbed to H₂S exposure at a waterflood station due to inadequate safety measures, underscoring the need for effective training in UAE refineries.

UAE Regulatory Framework

UAE refineries adhere to stringent safety standards to mitigate H₂S risks:

-

ADNOC HSE Policies: Mandate comprehensive H₂S training, personal protective equipment (PPE), and gas detection systems.

-

UAE Federal Law No. 8 of 1980: Requires employers to provide training and hazard mitigation measures.

-

OSHA Standards (Reference): UAE refineries often adopt OSHA’s 20 ppm permissible exposure limit (PEL) for H₂S (29 CFR 1910.1000) and annual training requirements.

-

NFPA 56: Provides guidelines for handling flammable gases like H₂S, emphasizing fire prevention and emergency response.

Non-compliance can result in fines, operational disruptions, and reputational damage, making hydrogen sulfide safety training videos a critical tool for compliance and worker safety.

How UAE Refineries Use Hydrogen Sulfide Safety Training Videos

UAE refineries leverage hydrogen sulfide safety training videos to protect workers by delivering engaging, visual, and standardized training. Below are the key ways these videos are utilized, with practical examples and benefits.

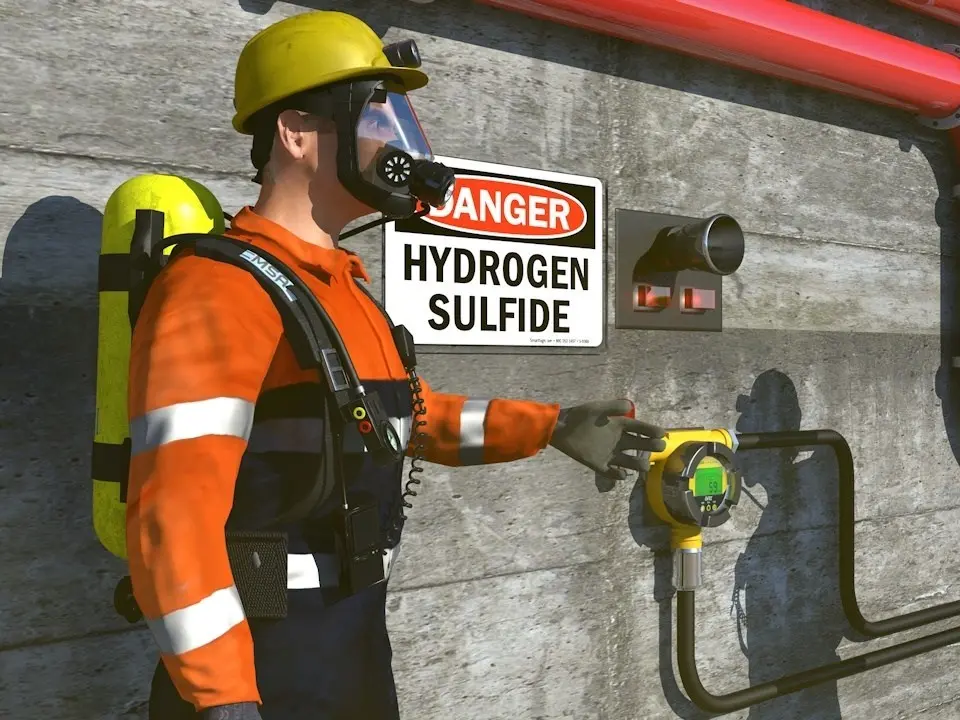

1. Educating Workers on H₂S Hazards

Hydrogen sulfide safety training videos simplify complex H₂S hazards for refinery workers by:

-

Visualizing Risks: 3D animations depict H₂S leaks in refinery settings, showing how gas accumulates in confined spaces like pump rooms or distillation units.

-

Demonstrating Detection: Videos illustrate the use of personal and area gas monitors to maintain H₂S levels below 20 ppm, aligning with OSHA’s PEL.

-

Example: A hydrogen sulfide safety training video at ADNOC’s Ruwais refinery shows a worker using a personal H₂S monitor to detect a leak during pipeline maintenance, highlighting safe evacuation procedures.

Benefit: Visual learning enhances understanding, especially for workers with limited technical or language proficiency, reducing the risk of H₂S-related incidents.

2. Training on Proper PPE Usage

OSHA and ADNOC require PPE, such as self-contained breathing apparatuses (SCBAs) and full-face respirators, for H₂S exposure risks. Hydrogen sulfide safety training videos demonstrate:

-

PPE Protocols: Proper donning and doffing of SCBAs for gas levels up to 100 ppm or supplied air lines for 100–1,000 ppm.

-

Maintenance Checks: Ensuring respirators are functional and fit-tested.

-

Example: A video shows a refinery worker donning an SCBA before entering a sour gas processing area, emphasizing ADNOC’s PPE compliance standards.

Benefit: Hands-on demonstrations ensure workers use PPE correctly, minimizing exposure risks.

3. Simulating Emergency Response Scenarios

H₂S incidents require swift, coordinated responses. Hydrogen sulfide safety training videos provide:

-

Evacuation Drills: Virtual simulations of H₂S leaks, showing workers navigating to safe zones or muster points.

-

First Aid Procedures: Demonstrating CPR or oxygen administration for H₂S exposure victims, as untrained responders risk secondary exposure.

-

Example: A hydrogen sulfide safety training video simulates an H₂S release in a Ruwais refinery pump room, guiding workers through ADNOC’s emergency action plan, including shutting off gas sources and using water sprays to extinguish fires.

Benefit: Safe simulations prepare workers for emergencies, aligning with NFPA 56 and ADNOC’s contingency planning requirements.

4. Ensuring ADNOC and Regulatory Compliance

Hydrogen sulfide safety training videos help refineries meet UAE and international standards by:

-

Documenting Training: Videos serve as auditable records of compliance with ADNOC HSE and OSHA training mandates.

-

Covering Key Topics: Detection (gas monitors), PPE (respirators), and emergency response (evacuation plans).

-

Example: A video tailored for ADNOC’s Habshan facility outlines OSHA’s 20 ppm PEL and NFPA 56 fire prevention protocols, ensuring regulatory alignment.

Benefit: Standardized videos reduce the risk of fines and enhance audit readiness.

5. Supporting Multilingual and Remote Training

UAE refineries employ diverse workforces, including Arabic, English, Hindi, and Urdu speakers, often in remote locations. Hydrogen sulfide safety training videos offer:

-

Multilingual Support: Subtitles or voiceovers in multiple languages to ensure accessibility.

-

Remote Access: Videos hosted on learning management systems (LMS) or mobile devices for workers at remote sites like Al Dhafra.

-

Example: A hydrogen sulfide safety training video with Arabic and English narration allows workers to review H₂S protocols before maintenance tasks.

Benefit: Flexible, inclusive training ensures all workers are prepared, regardless of language or location.

6. Enhancing Worker Engagement

Traditional training methods can be ineffective for diverse teams. Hydrogen sulfide safety training videos engage workers by:

-

Storytelling: Narratives of H₂S incidents (e.g., a worker safely evacuating after a leak) make training relatable.

-

Interactive Elements: Quizzes or clickable scenarios (e.g., “Choose the correct H₂S monitor response”) boost participation.

-

Example: A video uses a 3D-animated H₂S incident to engage workers, followed by a quiz on ADNOC’s safety protocols.

Benefit: Engaged workers retain safety knowledge, reducing errors and incidents.

7. Cost-Effective and Scalable Training

Hydrogen sulfide safety training videos are a one-time investment with long-term benefits:

-

Cost Savings: Reduce the need for repeated in-person sessions or trainers.

-

Scalability: Deployable across multiple ADNOC refineries or shifts.

-

Example: A single hydrogen sulfide safety training video serves workers at Ruwais and Habshan, updated periodically for new regulations.

Benefit: Cost-effective solutions maximize safety investments while ensuring compliance.

How to Create a Hydrogen Sulfide Safety Training Video for UAE Refineries

Creating an effective hydrogen sulfide safety training video for UAE refineries involves a structured process, leveraging animation and live-action techniques. Below is a step-by-step guide, inspired by industry practices like those of Chasing Illusions Studio.

1. Plan and Research for H₂S Safety Videos

-

Objectives: Focus on H₂S hazards, detection, PPE, and emergency response, aligned with ADNOC HSE and OSHA standards.

-

Consult Experts: Collaborate with refinery HSE officers and engineers.

-

Data Collection: Gather refinery layouts, equipment details, and H₂S scenarios.

-

Audience: Address UAE’s multilingual workforce.

Tips:

-

Create a storyboard for key scenes (e.g., H₂S leak in a pump room).

-

Reference OSHA 29 CFR 1910.1000 and NFPA 56.

2. Choose Animation or Live-Action

-

3D Animation: Ideal for simulating H₂S leaks in refineries (e.g., Blender, Autodesk Maya).

-

Live-Action: Demonstrates PPE usage or real-world procedures.

-

Hybrid: Combines animation for risks and live-action for practical tasks.

Tips:

-

Use animation for hazardous scenarios to ensure safety.

-

Film live-action in controlled environments.

3. Develop a Script and Storyboard

-

Script: Cover H₂S properties, detection, PPE, and ADNOC-compliant emergency procedures.

-

Storyboard: Sketch scenes like gas monitor alerts or evacuation drills.

-

Multilingual: Include Arabic, English, and Hindi voiceovers or subtitles.

Tips:

-

Keep videos 5–10 minutes for engagement.

-

Use clear language for accessibility.

4. Create Visuals for Hydrogen Sulfide Safety Training Videos

-

Modeling: Build 3D models of refinery assets (e.g., distillation towers, pipelines) in Blender.

-

Animation: Animate H₂S leaks or worker responses (e.g., donning an SCBA).

-

Texturing: Apply realistic textures (e.g., metal pipelines, desert settings) to mimic UAE refineries.

Tips:

-

Use ADNOC refinery photos for accuracy.

-

Optimize models for rendering efficiency.

5. Add Audio and Narration

-

Voiceover: Record with Audacity, using professional actors for clarity.

-

Sound Effects: Include alarms or machinery sounds from Freesound.org.

-

Music: Use subtle, royalty-free tracks from YouTube Audio Library.

Tips:

-

Prioritize narration clarity.

-

Balance audio levels to avoid distractions.

6. Edit and Polish the Video

-

Software: DaVinci Resolve (free) or Adobe Premiere Pro.

-

Annotations: Add text (e.g., “H₂S PEL: 20 ppm”) for clarity.

-

Interactivity: Include quizzes for LMS platforms.

Tips:

-

Use simple transitions (fades, cuts).

-

Export test versions for review.

7. Optimize and Distribute

-

Resolution: 1920×1080 for clear visuals.

-

Format: MP4 with H.264 codec for compatibility.

-

Distribution: Host on LMS, Vimeo (password-protected), or USB drives for remote sites.

Tips:

-

Compress with HandBrake (50–200 MB).

-

Test on mobile and VR devices.

8. Update and Maintain Training Videos

-

Updates: Revise for new ADNOC or OSHA regulations.

-

Feedback: Collect worker input for improvements.

-

Archiving: Store master files in ProRes for future edits.

Tips:

-

Schedule annual updates.

-

Use modular assets for easy edits.

Best Practices for Hydrogen Sulfide Safety Training Videos

-

Clarity: Ensure clear visuals and narration for H₂S risks.

-

Compliance: Align with ADNOC, OSHA, and NFPA standards.

-

Engagement: Use storytelling and multilingual support.

-

Conciseness: Keep videos 5–10 minutes.

-

Testing: Pilot with workers to verify effectiveness.

-

Collaboration: Work with HSE experts and animators.

Tools and Resources

-

Animation Software: Blender, Maya, Unreal Engine.

-

Editing Software: DaVinci Resolve, Adobe Premiere Pro.

-

Audio: Freesound.org, YouTube Audio Library.

-

Tutorials: Blender Guru, CG Cookie, Udemy.

-

Regulatory Resources: ADNOC.ae, OSHA.gov, NFPA.org.

-

Communities: Reddit’s r/animation, Blender Artists.

Challenges and Solutions

-

Challenge: Language barriers in diverse workforces.

-

Solution: Multilingual subtitles or voiceovers.

-

-

Challenge: Production costs.

-

Solution: Use free tools like Blender.

-

-

Challenge: Regulatory updates.

-

Solution: Modular video designs.

-

-

Challenge: Remote worker engagement.

-

Solution: Mobile and VR accessibility.

-

Hydrogen sulfide safety training videos are indispensable for UAE refineries, protecting workers from H₂S hazards through engaging, compliant, and scalable training. By visualizing risks, demonstrating PPE usage, and simulating emergencies, these videos ensure ADNOC compliance and foster safety. Using tools like Blender, refineries can create effective training solutions, safeguarding workers in 2025 and beyond.