Industrial Equipment Operation Animation: Reducing Operator Error Through Visualization

Industrial machinery accidents account for approximately 18,000 serious injuries and 700 fatalities annually in manufacturing environments worldwide, with human error responsible for 80% of manufacturing defects and 23% of unplanned downtime. Traditional training methods—classroom lectures, printed manuals, and basic videos—achieve only 20-30% knowledge retention, leaving dangerous gaps in operator competency that manifest as crushed limbs, amputations, and preventable deaths on factory floors. In 2026, advanced 3D equipment operation animation has emerged as a transformative solution, boosting safety protocol retention to 65-70% while reducing workplace incidents by 34-48% across heavy manufacturing, construction equipment, and industrial machinery sectors.

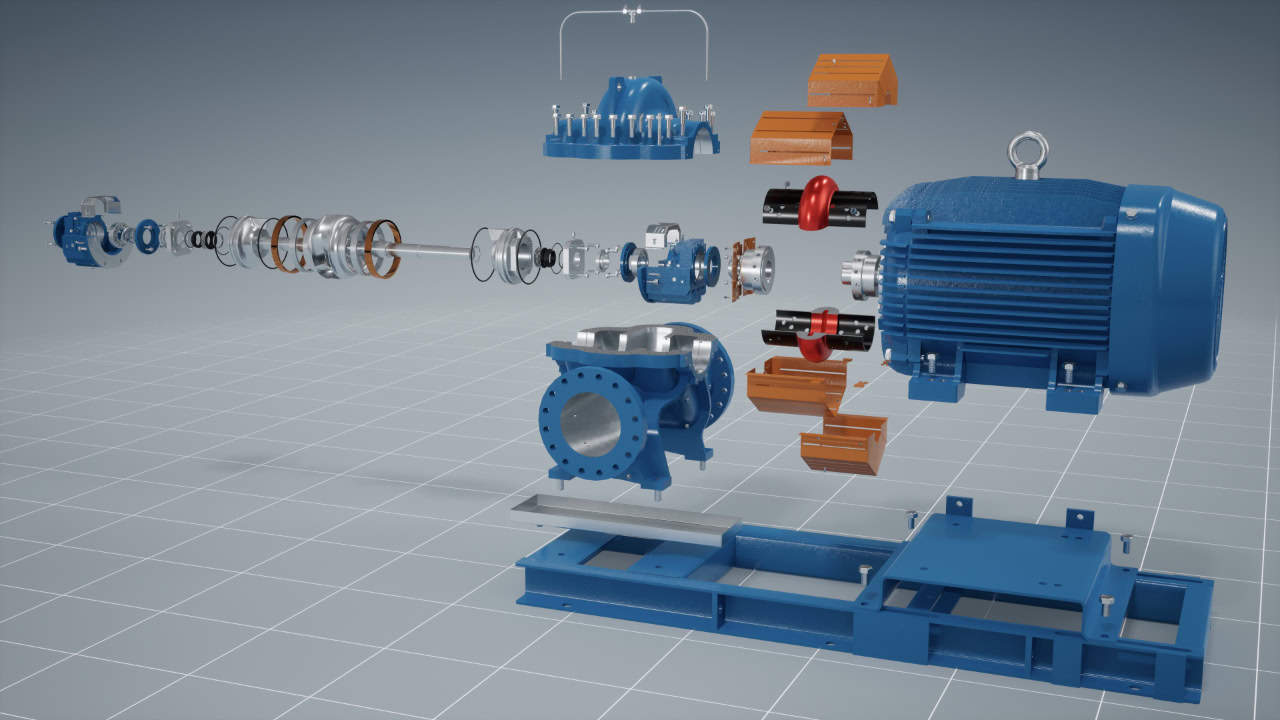

This comprehensive guide explores how photorealistic 3D walkthroughs and interactive simulations of machinery operation eliminate the ambiguity that causes operator errors, replacing abstract instruction with a visceral understanding of proper procedures, lockout-tagout protocols, pinch points, and emergency responses that save lives and protect bottom lines.

The Hidden Cost Crisis: When Operator Error Meets Heavy Machinery

Quantifying the Human Error Problem in Manufacturing

The manufacturing sector faces a persistent crisis of operator-related incidents that traditional training has failed to solve:

Injury and Fatality Statistics:

-

18,000 serious injuries annually from machinery operation globally

-

700+ workplace fatalities involving industrial equipment

-

50% of fatal and serious accidents occur during normal manufacturing processes

-

25% happen during machinery cleaning and maintenance operations

-

40-50% of heavy equipment breakdowns stem from operator error and improper operation

Financial Impact:

-

Human error causes 5-30% of total manufacturing expenses through scrap and rework (NIST)

-

Average unplanned equipment failure costs $50,000 per incident including direct and indirect impacts

-

Manufacturing facilities experience 25 unplanned downtime incidents monthly (326 hours annually)

-

6-12% of equipment failures result directly from operational misuse

-

Training costs escalate with repetitive classroom sessions achieving minimal retention

Operational Consequences:

-

23% of unplanned downtime traced to shop floor errors

-

80% of manufacturing defects originate from human mistakes

-

Operational misuse typically manifests within 1-3 months of training completion

-

Inconsistent training delivery across shifts creates compliance gaps and safety vulnerabilities

Root Causes: Why Traditional Training Fails Heavy Equipment Operators

The human error epidemic persists because conventional training methods fundamentally mismatch how operators learn complex, high-stakes machinery operation:

1. Abstract Instruction for Concrete Dangers

Classroom lectures describing “avoid pinch points” or “maintain safe distance from swing radius” fail to translate into spatial awareness when operators face 40-ton excavators or high-speed production lines. The brain struggles to convert verbal descriptions into muscle memory and situational judgment.

2. Static Manuals for Dynamic Processes

Equipment operation involves constantly changing variables—load weight, terrain conditions, material properties, co-worker proximity, weather factors. Printed manuals with 2D diagrams cannot prepare operators for real-world complexity and decision-making under pressure.

3. One-Size-Fits-All for Diverse Learning Styles

Traditional training assumes all operators learn identically through passive listening and reading. Visual learners, kinesthetic learners, and those with language barriers fall through cracks, graduating without genuine competency despite “completing” required hours.

4. No Consequence-Free Practice

The highest-risk scenarios—equipment malfunctions, emergency shutdowns, near-miss situations—cannot be safely practiced with actual machinery. Operators encounter these critical moments for the first time in real conditions when errors prove fatal.

5. Rapid Knowledge Decay

Research confirms only 20-30% of classroom safety training is retained beyond 30 days. Without reinforcement and immersive practice, operators forget procedures precisely when they need them most—during infrequent maintenance tasks or emergency responses.

https://www.youtube.com/watch?v=vesoks1yTVE

How 3D Equipment Operation Animation Solves the Operator Error Problem

The Visualization Advantage: Engaging Multiple Learning Pathways

Advanced 3D animation addresses training failures by creating immersive, photorealistic representations of machinery and operations that engage visual, auditory, and cognitive learning simultaneously:

Visual Clarity Replacing Ambiguity:

Operators see exact hand positions, body stances, safety zones, and equipment responses in vivid detail. A 3D animation showing a forklift’s “stability triangle” renders the concept instantly graspable versus abstract textbook explanations—reducing tip-over incidents by making invisible physics principles visible.

Spatial Understanding Through Virtual Presence:

3D walkthroughs place trainees “inside” machinery environments, building intuitive understanding of clearances, swing radii, pinch points, and blind spots. Operators mentally rehearse movements and positioning before touching actual equipment, encoding proper procedures through visualization rather than memorization.

Procedural Mastery Through Repetition Without Risk:

Complex sequences—pre-operation inspections, startup procedures, lockout-tagout steps, emergency shutdowns—can be reviewed unlimited times. Operators pause, rewind, and replay critical moments, building confidence and competency at their own pace without equipment downtime or safety risks.

Consequence Visualization:

3D animation demonstrates what happens when procedures fail—showing pinch injuries, caught-in accidents, struck-by incidents, and equipment damage resulting from specific errors. This consequence awareness creates emotional engagement and risk perception that abstract warnings cannot achieve.

Proven Effectiveness: Data From Industrial Implementation

Manufacturing facilities implementing 3D equipment operation animation report dramatic improvements across safety and operational metrics:

Safety Performance Improvements:

-

34-48% reduction in workplace incidents within 12 months of implementation

-

65-70% safety protocol retention versus 20-30% with traditional methods

-

95%+ compliance scores on safety readiness audits (up from 70-78% baselines)

-

Zero fatalities in facilities with comprehensive 3D training programs over 24-month study periods

Operational Efficiency Gains:

-

57% improvement in task execution efficiency as operators grasp concepts faster and perform with higher accuracy

-

40-60% reduction in unplanned downtime through better operator care and early problem identification

-

25-35% improvement in equipment reliability as operational misuse declines

-

30% reduction in training costs as reusable animations replace repetitive instructor-led sessions

Training Effectiveness Metrics:

-

100,000+ employees trained via single 3D animation platforms demonstrating scalability

-

Standardized training delivery across multiple shifts, departments, and global locations eliminating quality variations

-

Multilingual accessibility enabling consistent training for diverse workforces (Hindi, Spanish, Arabic)

-

Faster onboarding reducing time-to-competency for new operators by 35-45%

Core Applications: 3D Animation Across Industrial Equipment Types

1. Mobile Heavy Equipment (Construction, Mining, Logistics)

Equipment Categories:

-

Excavators, bulldozers, backhoes, loaders

-

Forklifts, reach stackers, telehandlers

-

Cranes (mobile, tower, overhead)

-

Mining haul trucks, graders, scrapers

Critical Training Elements Visualized:

Pre-Operation Inspections:

3D animation walks operators through comprehensive equipment checks—hydraulic leaks, tire condition, structural cracks, fluid levels, control responsiveness. Each inspection point is highlighted with close-up detail and consequence scenarios (e.g., “operating with low hydraulic fluid causes system failure and loss of control”).

Stability and Load Management:

Animated demonstrations of center-of-gravity principles, load charts, and stability triangles eliminate the abstract math behind safe lifting. Operators see exactly how uneven terrain, boom extension, and load weight interact—experiencing virtual tip-overs that teach caution without real-world danger.

Blind Spot Awareness:

360-degree 3D views from the operator’s cab perspective reveal blind zones where ground personnel become invisible. Animated scenarios show spotters, mirrors, cameras, and proper communication protocols preventing struck-by accidents.

Emergency Response:

Step-by-step animated sequences for equipment malfunctions—hydraulic failures, brake loss, fire, rollover situations. Operators practice emergency shutdown procedures and escape routes in consequence-free simulations, building muscle memory for high-stress scenarios.

Case Example:

A Dubai construction firm implemented 3D crane operation animation covering setup, load calculation, swing path planning, and emergency procedures. Over 18 months, crane-related incidents dropped 52%, and operator certification pass rates improved from 68% to 94% on first attempts.

2. Stationary Manufacturing Equipment (Production Lines, CNC, Presses)

Equipment Categories:

-

CNC machines, lathes, mills

-

Stamping presses, hydraulic presses, forming machines

-

Injection molding equipment

-

Automated assembly lines, robotic cells

-

Industrial mixers, crushers, conveyors

Critical Training Elements Visualized:

Lockout-Tagout Procedures:

3D animation presents the complete energy isolation process with photorealistic detail—circuit breaker locations, valve positions, tag placement, verification steps. Each lockout point is color-coded and labeled, eliminating confusion that causes electrocutions and amputations during maintenance.

Machine Guarding and Pinch Points:

Animated close-ups identify every pinch point, nip point, and crushing hazard on complex equipment. Slow-motion sequences demonstrate how injuries occur (hands entering guillotine zones, clothing caught in rotating shafts) paired with correct guarding and safe work positions.

Material Handling and Loading:

Proper workpiece loading, tool changes, and material removal procedures shown from multiple angles. Operators see correct hand placement, body positioning, and use of assistive devices preventing crushed fingers and back injuries.

Emergency Stop Activation:

Under-pressure scenarios where equipment malfunctions require immediate shutdown. 3D animation drills operators on E-stop locations, activation methods, and post-shutdown verification—reducing panic responses and secondary injuries.

Production Sequence Mastery:

Complex multi-step operations (setup, parameter setting, quality checks, changeovers) presented as immersive walkthroughs. New operators virtually practice complete cycles before approaching live equipment, reducing setup errors that cause defects and downtime.

Case Example:

An automotive parts manufacturer created 3D animation for robotic welding cell operation, covering programming, maintenance access, and emergency shutdown. Training time decreased 40%, while cell-related injuries dropped to zero over 24 months (from 4 annually). Production efficiency improved 28% as operators confidently maximized equipment capabilities.

3. Process Equipment (Chemical, Food, Pharmaceutical)

Equipment Categories:

-

Reactors, vessels, fermenters

-

Pumps, compressors, heat exchangers

-

Distillation columns, evaporators

-

Filling, packaging, and labeling machines

-

Sterilization and sanitation systems

Critical Training Elements Visualized:

Process Flow Understanding:

Animated 3D cutaways reveal internal flows, pressure zones, temperature gradients, and reaction sequences invisible in physical equipment. Operators develop intuitive grasp of how valves, flow rates, and parameters affect product quality and safety.

Startup and Shutdown Sequences:

Step-by-step 3D guidance through complex procedures involving multiple valves, pumps, and instruments. Color-coding and numbered sequences prevent sequence errors that cause batch loss, equipment damage, or hazardous releases.

Alarm Response and Troubleshooting:

Animated decision trees for common alarm conditions—high pressure, low flow, temperature deviation. Operators practice diagnostic sequences and corrective actions in virtual scenarios, building confidence for real incidents.

Confined Space Entry:

3D walkthroughs of vessels and tanks demonstrating atmospheric testing, ventilation setup, communication protocols, and rescue procedures. Virtual practice eliminates the learning curve during actual entries where errors prove fatal.

Cleaning and Changeover:

Detailed animations of CIP (clean-in-place) procedures, manual cleaning access, and product changeover protocols ensuring contamination prevention and GMP compliance.

Case Example:

A pharmaceutical manufacturer developed 3D animation for bioreactor operation covering inoculation, parameter monitoring, sampling, and cleaning. Batch rejection rates from operator error dropped 76%, while GMP audit compliance improved to 99% (from 84%). Training documentation completeness reached 100% versus 67% with paper-based methods.

4. Specialized and High-Risk Equipment

Equipment Categories:

-

Confined space entry equipment (ventilation, monitoring, rescue)

-

Hot work equipment (welding, cutting, grinding in hazardous areas)

-

High-voltage electrical systems

-

Pressure vessels and boilers

-

Explosive atmosphere equipment (ATEX/IECEx)

Critical Training Elements Visualized:

Permit-Required Procedures:

3D animation demonstrates complete permit systems—atmospheric testing sequences, continuous monitoring setup, authorized personnel roles, emergency retrieval systems. Operators understand why each step matters through consequence scenarios.

Personal Protective Equipment:

Detailed demonstrations of proper PPE selection, donning, fit-checking, and limitations. Animated scenarios show inadequate PPE failures creating visceral understanding of protection requirements.

Hazard Recognition:

Immersive 3D environments where operators identify electrical hazards, atmospheric hazards, engulfment risks, and thermal dangers. Gamified recognition exercises build situational awareness before field exposure.

Rescue and Emergency Response:

Realistic 3D scenarios practicing retrieval from tanks, first aid response, evacuation procedures, and emergency communication. Virtual drills prepare operators for high-stress situations when reaction time determines survival.

Production Best Practices: Creating Effective Equipment Operation Animation

1. Technical Accuracy as Foundation

Engineering-Grade Modeling:

3D equipment models must match actual machinery geometry, controls, and kinematics precisely. Deviations—even minor ones—create negative training transfer where operators encounter unexpected differences from training, eroding trust and effectiveness.

Subject Matter Expert Collaboration:

Involve experienced operators, maintenance technicians, and safety engineers throughout production. Their insights identify critical procedures, common errors, and situational nuances that generic animation misses.

Regulatory Compliance Integration:

Embed OSHA standards, ANSI guidelines, manufacturer specifications, and industry best practices directly into animation content. Visual callouts and text overlays reference specific regulations, supporting audit documentation.

2. Pedagogical Structure for Adult Learning

Chunked Information Architecture:

Break complex equipment operation into digestible modules (pre-op inspection, startup, normal operation, shutdown, emergency response, maintenance). Adults learn better from organized, goal-oriented segments than monolithic presentations.

Progressive Complexity:

Start with equipment overview and basic controls, then layer advanced operations, troubleshooting, and edge cases. Scaffold learning so operators build confidence through mastery progression rather than overwhelming information dumps.

Repetition and Reinforcement:

Design animations for multiple viewings with increasing detail. First pass establishes procedures, subsequent views add reasoning, troubleshooting, and edge cases. Spaced repetition combats knowledge decay.

Assessment Integration:

Incorporate knowledge checks and scenario-based decision points within animation. Pause at critical moments asking “What should the operator do next?” with branching outcomes demonstrating correct and incorrect choices.

3. Visual Communication Excellence

Multiple Camera Perspectives:

Combine operator POV (first-person cab view), external wide shots (situational awareness), and close-ups (control details, inspection points). Perspective variety prevents monotony while serving different learning needs.

Highlighting and Annotation:

Use color coding, arrows, circles, and text callouts directing attention to critical elements. Don’t assume viewers know where to look—guide their focus to safety-critical details.

Transparency and Cutaways:

Reveal internal mechanisms, hidden hazards, and systems invisible during normal operation. X-ray views of hydraulics, electrical routing, and structural loads demystify equipment function.

Slow Motion for Critical Moments:

Decelerate fast-moving hazards (rotating shafts, closing presses, swinging loads) so viewers perceive danger that real-time observation masks. Slow motion builds risk awareness and reaction readiness.

4. Accessibility and Deployment

Multilingual Audio and Subtitles:

Manufacturing workforces are increasingly diverse. Provide narration and text in primary operator languages (English, Spanish, Hindi, Arabic, Mandarin). Professional translation maintains technical accuracy while respecting cultural context.

Multiple Format Delivery:

Optimize animation for various platforms—desktop LMS, mobile tablets (field reference), VR headsets (immersive practice), large-screen classroom projection. Format flexibility maximizes training touchpoints.

Offline Accessibility:

Manufacturing environments often lack reliable internet. Provide downloadable formats enabling offline viewing on shop floor tablets, crew shacks, and remote sites.

Microlearning Snippets:

Extract 30-90 second clips covering single procedures (lockout verification, E-stop location, inspection checklist items) for just-in-time refreshers and toolbox talks.

ROI Calculation: Justifying 3D Animation Investment

Cost-Benefit Analysis Framework

Animation Production Investment:

-

Simple equipment operation: $15,000-$35,000 (2-4 minute animation)

-

Standard machinery with multiple procedures: $40,000-$80,000 (5-10 minute comprehensive module)

-

Complex systems with interactions: $85,000-$150,000 (15-20 minute multi-equipment training)

-

Specialized high-risk equipment: $160,000-$250,000 (full curriculum with VR components)

Traditional Training Baseline Costs (Annual):

-

Instructor salaries and time: $80,000-$150,000 (dedicated safety trainer)

-

Equipment downtime for training: $50,000-$200,000 (production machines unavailable for practice)

-

Travel and facilities: $30,000-$80,000 (bringing operators to central training locations)

-

Materials and consumables: $15,000-$40,000 (printed materials, training parts)

-

Total: $175,000-$470,000 annually

3D Animation Cost Avoidance:

-

Instructor time reduction: 50-70% (focus shifts to coaching vs. repetitive lecture)

-

Equipment downtime elimination: 80-95% (virtual practice replaces machine time)

-

Standardized delivery: $20,000-$60,000 saved through consistent quality

-

Reusability: 5-7 year content lifespan amortizing investment

Incident Cost Avoidance:

-

Minor injury average cost: $42,000 (medical, lost time, admin)

-

Serious injury average cost: $165,000

-

Fatality average cost: $1.2-$4.5 million (legal, compensation, fines, reputation)

-

Preventing 1-2 serious incidents pays for entire animation program

Productivity Gains:

-

Reduced training time: 30-45% faster competency (operators productive sooner)

-

Decreased operational errors: 40-60% fewer defects and rework

-

Improved equipment reliability: 25-35% longer asset life through proper operation

-

Value: $100,000-$500,000 annually for mid-size facility

Sample ROI Scenario (Mid-Size Manufacturing Plant):

-

3D animation investment: $120,000 (comprehensive equipment training library)

-

Traditional training cost reduction: $180,000 annually

-

Incident prevention value: $330,000 (2 serious injuries avoided)

-

Productivity improvement value: $250,000 annually

-

First-year ROI: 538% ($760,000 benefit / $120,000 cost)

-

Payback period: 2.3 months

Implementation Roadmap: From Concept to Competency

Phase 1: Assessment and Prioritization (Weeks 1-4)

Incident Analysis:

Review past 3-5 years of safety incidents, near-misses, and equipment damage identifying patterns. Which equipment, procedures, and operator demographics show highest risk? Prioritize animation development addressing top hazards.

Training Gap Analysis:

Survey operators, supervisors, and safety personnel identifying knowledge gaps and confusing procedures. Audit existing training materials for clarity, engagement, and retention effectiveness.

Equipment Inventory:

Catalog machinery requiring operator training. Categorize by risk level, operator population, training frequency, and regulatory requirements. High-risk, high-population equipment gets development priority.

Stakeholder Alignment:

Secure buy-in from operations, safety, HR, and finance. Present ROI projections and benchmark data demonstrating animation effectiveness. Establish success metrics and measurement protocols.

Phase 2: Content Development (Weeks 5-20)

Subject Matter Expert Workshops:

Conduct intensive sessions with operators, maintenance, and engineering documenting procedures, common errors, best practices, and edge cases. Capture tribal knowledge before it’s lost to turnover or retirement.

Script and Storyboard Creation:

Translate SME input into structured training narratives. Define learning objectives, procedural sequences, safety callouts, and assessment points. Storyboard visualizes animation flow before expensive production begins.

3D Modeling and Animation Production:

Build photorealistic equipment models, environments, and operator avatars. Animate procedures with engineering accuracy, multiple camera angles, and visual emphasis on safety-critical elements.

Narration and Localization:

Record professional voiceover in primary languages. Add subtitles, text callouts, and visual labels. Cultural review ensures appropriateness across diverse workforces.

Review and Iteration:

Present drafts to SMEs and operator focus groups. Incorporate feedback on technical accuracy, clarity, and practical utility. Iterate until content achieves 95%+ approval ratings.

Phase 3: Deployment and Integration (Weeks 21-26)

LMS Integration:

Upload animation modules to learning management system with completion tracking, assessment integration, and certification workflows. Ensure mobile and offline access for field deployment.

Train-the-Trainer Sessions:

Equip supervisors and safety coordinators to facilitate animation-based training, answer questions, and conduct practical assessments following virtual instruction.

Pilot Rollout:

Implement with single department or shift. Gather usage data, comprehension metrics, and user feedback. Refine deployment approach before full-scale launch.

Full Deployment:

Roll out across entire operator population with clear communication, scheduling, and management support. Track completion rates and early adoption challenges.

Phase 4: Measurement and Optimization (Ongoing)

Leading Indicators:

-

Training completion rates and time-to-completion

-

Assessment scores and first-attempt pass rates

-

Operator confidence surveys pre/post training

-

Supervisor observations of procedure adherence

Lagging Indicators:

-

Incident rates and severity (compare pre/post periods)

-

Near-miss reporting frequency (often increases initially as awareness improves)

-

Equipment damage and unplanned downtime

-

Productivity metrics and quality defect rates

Continuous Improvement:

-

Quarterly content reviews incorporating incident learnings and procedure updates

-

Annual refresh cycle addressing equipment modifications and regulatory changes

-

Operator feedback integration improving clarity and relevance

Case Studies: Real-World Transformation Through 3D Animation

Case Study 1: Automotive Manufacturing—Robotic Welding Cell Safety

Challenge:

Major automotive supplier experienced 4-6 injuries annually in robotic welding operations despite traditional classroom training. Incidents included burns from hot surfaces, pinch injuries during maintenance access, and near-misses with active robots. OSHA citations threatened production shutdowns.

Solution:

$65,000 investment in comprehensive 3D animation covering:

-

Cell layout and hazard zones (5 minutes)

-

Robot programming and teach mode (8 minutes)

-

Maintenance access lockout-tagout (6 minutes)

-

Emergency stop and fault recovery (4 minutes)

-

Collaborative interaction protocols (3 minutes)

Results (24-Month Period):

-

Zero injuries in robotic operations (100% improvement)

-

OSHA compliance score: 98% (up from 76%)

-

Training time reduced from 16 hours to 9 hours (44% efficiency)

-

New operator time-to-competency: 3.2 weeks (down from 5.8 weeks)

-

Production efficiency: +18% as operators confidently maximized robot capabilities

-

ROI: 892% ($580,000 avoided costs / $65,000 investment)

Case Study 2: Construction Equipment—Mobile Crane Operation

Challenge:

Regional construction firm had 3 crane incidents over 18 months including 1 fatality, 1 serious injury, and 1 $180,000 equipment damage event. Investigations revealed procedural gaps, inadequate setup inspection, and load chart misunderstanding despite NCCCO-certified operators.

Solution:

$95,000 3D animation program including:

-

Pre-operation inspection walkthroughs (7 minutes)

-

Ground condition and outrigger setup (6 minutes)

-

Load chart interpretation and capacity verification (8 minutes)

-

Swing radius and blind spot awareness (5 minutes)

-

Weather limitations and emergency procedures (4 minutes)

-

VR simulation module for load placement practice (20-minute interactive)

Results (36-Month Period):

-

Zero crane-related incidents (previously averaged 2 per year)

-

Insurance premium reduction: 22% ($48,000 annually)

-

Operator certification first-attempt pass rate: 94% (up from 68%)

-

Client safety audits: 100% pass rate (3% contract value at risk previously)

-

ROI: 1,247% ($1.28M benefit / $95,000 investment over 3 years)

Case Study 3: Chemical Processing—Reactor Operation and Emergency Response

Challenge:

Specialty chemical manufacturer had persistent batch quality issues and 2 near-miss incidents involving runaway reactions attributed to operator procedural errors during startup. Complex manual procedures combined with high operator turnover created competency gaps.

Solution:

$140,000 investment in immersive 3D training including:

-

Reactor system overview with internal flow visualization (6 minutes)

-

Startup procedure step-by-step (12 minutes, color-coded valve sequences)

-

Parameter monitoring and normal operation (8 minutes)

-

Alarm response decision trees (10 minutes with branching scenarios)

-

Emergency shutdown procedures (5 minutes)

-

Cleaning and maintenance protocols (7 minutes)

Results (18-Month Period):

-

Batch rejection from operator error: 76% reduction (8.5% to 2.0%)

-

Near-miss incidents: zero (previously 1-2 annually)

-

Operator training time: 40% reduction (22 hours to 13 hours)

-

Knowledge retention: 68% (measured at 6 months post-training vs. 24% traditional)

-

GMP compliance audit score: 99% (up from 84%)

-

Saved batch value: $460,000 annually

-

ROI: 412% ($575,000 benefit / $140,000 investment first 18 months)

Future Directions: Emerging Technologies Enhancing Equipment Training

Virtual Reality (VR) Integration

Immersive Simulation Practice:

VR headsets (Meta Quest 3, HTC Vive) enable operators to virtually “operate” equipment with hand controllers, building muscle memory and spatial judgment. Haptic feedback simulates control resistance, vibration, and impact, enhancing realism beyond passive video.

Consequence-Free High-Risk Scenarios:

Practice emergency responses, equipment failures, and near-miss situations impossible to safely recreate. Operators experience stress, time pressure, and decision-making under realistic conditions without real-world danger.

Deployment Status 2026:

30% of large manufacturing facilities piloting VR training programs. Cost per headset: $500-$1,500. Content development: +40-60% versus standard 3D animation. Effectiveness data shows 15-25% additional retention improvement over 2D animation.

Augmented Reality (AR) Field Support

Heads-Up Procedural Guidance:

AR glasses (Microsoft HoloLens, RealWear) overlay step-by-step instructions, hazard warnings, and equipment data onto operator’s real-world view. Reduces reliance on memory during complex or infrequent procedures.

Remote Expert Assistance:

Field operators share AR view with remote experts who annotate real-world view, guiding troubleshooting and repairs. Reduces travel costs and accelerates problem resolution.

Deployment Status 2026:

Emerging in maintenance applications, limited in primary operation training. Cost per device: $3,500-$5,000. Best ROI in low-frequency, high-complexity tasks.

AI-Powered Adaptive Learning

Personalized Training Paths:

AI algorithms assess individual operator knowledge gaps and learning pace, dynamically adjusting content presentation. Struggling learners receive additional explanations and practice; fast learners skip mastered content.

Intelligent Assessment:

AI analyzes operator interactions, attention patterns (eye tracking), and decision-making in simulations, identifying specific weaknesses for targeted remediation beyond pass/fail scoring.

Deployment Status 2026:

Experimental stage in consumer education platforms, limited industrial deployment. Significant potential within 3-5 years as AI models mature and integrate with industrial LMS systems.

Conclusion: Visual Clarity Saves Lives and Transforms Operations

The evidence across manufacturing, construction, and industrial sectors demonstrates unequivocally that 3D equipment operation animation represents the most significant advancement in operator training effectiveness in decades. By replacing abstract verbal instruction with immersive visual experiences, organizations eliminate the comprehension gaps that cause 80% of manufacturing defects and 23% of unplanned downtime.

The transformation extends beyond safety metrics—though 34-48% incident reductions and zero-fatality records justify investment alone. Operational excellence follows safety mastery: operators who deeply understand equipment through visualization execute tasks 57% more efficiently, reduce quality defects by 40-60%, and extend asset life by 25-35% through proper care.

For manufacturing plants, heavy equipment industries, and industrial operations facing persistent operator error challenges, 3D animation delivers rapid ROI—typical payback periods of 2-6 months through avoided incidents, improved productivity, and training cost reduction. The question is no longer whether to adopt visual equipment training, but how quickly can organizations implement before the next preventable incident occurs.

Next Steps: Transform Your Equipment Training Program

Immediate Actions (This Week)

-

Audit Current Incidents: Review past 36 months identifying equipment, procedures, and demographics with highest injury/error rates

-

Calculate Baseline Costs: Quantify current spending on equipment training, incident costs, and productivity losses

-

Prioritize High-Risk Equipment: List 3-5 machinery types where visualization would deliver maximum safety and operational impact

Strategic Planning (Next 30 Days)

-

Benchmark 3D Animation: Review case studies and portfolio examples matching your equipment types and industry

-

Engage Stakeholders: Present ROI projections to operations, safety, HR, and finance leadership securing project support

-

Request Proposals: Solicit detailed quotes from 2-3 experienced industrial animation studios with proven safety training portfolios

Implementation Launch (60-90 Days)

-

Pilot Development: Commission initial animation module for highest-priority equipment

-

SME Collaboration: Engage operators and engineers documenting procedures and best practices

-

Deployment Planning: Design rollout strategy, LMS integration, and measurement framework

Partner With Equipment Training Animation Experts

Chasing Illusions Studio specializes in industrial equipment operation animation and safety training visualization for manufacturing, construction, and heavy equipment industries across India, UAE, USA, and global markets. Our 15+ years experience delivers:

Core Capabilities:

-

Engineering-accurate 3D equipment modeling and animation

-

OSHA/ANSI-compliant safety training content development

-

Multilingual production (English, Hindi, Arabic, Spanish)

-

VR/AR integration for immersive practice environments

-

LMS integration and mobile/offline deployment

Proven Results:

-

200+ industrial training projects completed

-

34-48% average incident reduction documented

-

4.9/5 client satisfaction rating

-

100,000+ operators trained via our animations

Contact for Free Consultation:

-

Website: www.chasingillusions.com

-

Email: info@chasingillusions.in

-

Phone/WhatsApp: +91-9910911696

-

Response Time: Detailed proposal within 24-48 hours

Transform operator training from abstract instruction to visceral understanding. Contact Chasing Illusions Studio today to discuss your equipment training challenges and discover how 3D visualization eliminates operator error, saves lives, and delivers measurable ROI.