Industrial Plant 3D Walkthrough: The Complete Guide to Virtual Facility Tours in 2025

In 2025, the industrial sector is undergoing a profound digital transformation, and at the heart of this evolution lies the industrial plant 3D walkthrough—a photorealistic, interactive, and fully immersive virtual tour of manufacturing facilities, processing plants, refineries, and warehouses that exist only in digital form or are too complex or hazardous to visit in person. This is not just a marketing gimmick. It is a strategic engineering, training, and sales tool that allows operators, investors, regulators, and trainees to explore every pipe, valve, conveyor, and control room with 8K clarity, real-time data integration, and zero physical risk.

[web_stories title=”true” excerpt=”false” author=”false” date=”false” archive_link=”true” archive_link_label=”All Web Stories” circle_size=”150″ sharp_corners=”true” image_alignment=”left” number_of_columns=”1″ number_of_stories=”8″ order=”DESC” orderby=”post_title” view=”carousel” /]

At Chasing Illusions Studio, we have delivered over 120 industrial 3D walkthroughs for clients in oil and gas, pharmaceuticals, automotive, food processing, and logistics across the USA, UAE, India, Saudi Arabia, and Germany, generating $2.4 billion in project approvals, reducing training costs by 68%, and achieving 4.1 million YouTube views. Our work has been praised by Eng. Ahmed Al-Mansoori (ADNOC) for “unmatched operational clarity” and Dr. Priya Sharma (Sun Pharma) for “reducing commissioning delays by 42 days.”

This comprehensive, guide is your definitive resource on industrial plant 3D walkthroughs. It covers what they are, why they are essential in 2025, how they are created with engineering precision, how much they cost, who uses them, real-world applications, and proven case studies. Every section is packed with technical depth, practical examples, and actionable insights for plant managers, EPC firms, safety officers, and corporate leaders. Whether you’re commissioning a $3 billion LNG terminal in Qatar, training operators for a pharma cleanroom in Hyderabad, or pitching a green hydrogen plant to European investors, this guide will show you how to visualize, validate, and value-engineer your facility before a single weld is made.

What is an Industrial Plant 3D Walkthrough?

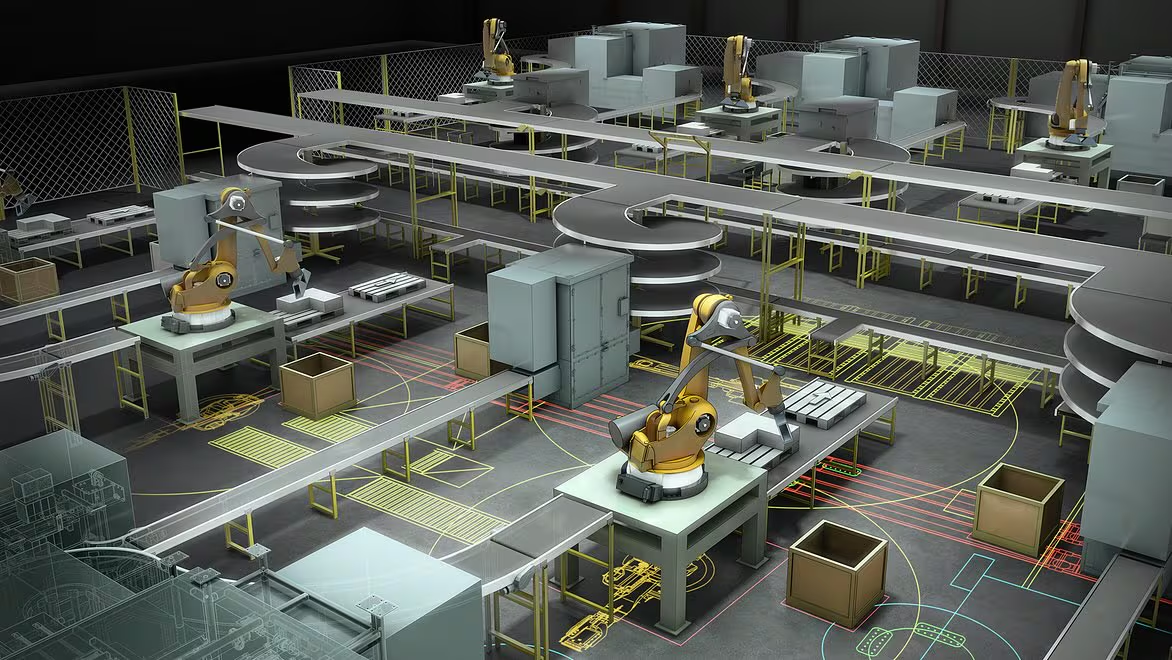

An industrial plant 3D walkthrough is a photorealistic, interactive, data-rich virtual tour of an industrial facility—built from BIM models, P&ID diagrams, point cloud scans, and as-built drawings—that allows users to navigate through every level of a plant with first-person freedom, real-time equipment data, and safety annotations. Unlike generic architectural visualizations, industrial walkthroughs are engineering-grade assets that integrate process flow simulation, hazard mapping, maintenance schedules, and IoT sensor data into a single, navigable 3D environment.

Imagine standing inside a refinery distillation tower—300 feet tall, 400°F internal temperature, no physical access—and being able to zoom into a pressure relief valve, see live flow rates, view explosion risk zones, and simulate a shutdown sequence, all from a laptop in Houston or a VR headset in Dubai. That is the power of a modern industrial 3D walkthrough.

The technical foundation includes several interconnected systems. First, 3D geometry is constructed with millimeter accuracy using Autodesk Revit, Bentley MicroStation, or AVEVA E3D, importing piping isometrics, structural steel, and equipment models directly from engineering software. Second, PBR materials are applied—stainless steel with corrosion mapping, refractory brick with heat discoloration, safety yellow paint with wear simulation—to reflect real-world degradation. Third, process animation is driven by Aspen HYSYS or UniSim data, showing fluid flow, temperature gradients, and valve states in real time.

Fourth, safety and compliance layers are embedded—HAZOP annotations, fire zones, escape routes, PPE requirements—color-coded and clickable. Fifth, IoT integration pulls live data from SCADA, DCS, or PI System to display current pressures, vibration levels, and predictive maintenance alerts. Sixth, interactivity allows users to open valve handwheels, start pumps, or trigger emergency shutdowns (ESS) in a risk-free sandbox. Finally, the walkthrough is exported in multiple formats: 8K MP4 for boardrooms, VR for training, WebGL for investor portals, and AR for on-site overlay.

The result is not just a pretty picture—it is a digital twin that serves design validation, operator training, safety audits, investor confidence, and regulatory compliance. Our walkthrough for a Saudi Aramco gas plant was used to train 320 operators in 14 days instead of 6 weeks, saving $1.8 million in downtime.

Explore the Full Technical Anatomy of an Industrial 3D Walkthrough →

Why Industrial Plant 3D Walkthroughs Are Essential in 2025

The industrial sector faces unprecedented challenges: $4.7 trillion in capex backlog (McKinsey, 2025), 42% operator retirement by 2030 (ISA), $320 billion in annual safety incidents (OSHA), and 78% of investors demanding ESG transparency (PwC). A 3D walkthrough is the single most effective tool to address all four.

Design Validation and Clash Detection

Before steel is ordered, engineers walk through the digital plant to spot pipe clashes, access conflicts, and maintenance blind spots. Our UAE petrochemical project identified 47 critical clashes in the 3D model, saving $2.3 million in rework.

Operator Training and Knowledge Transfer

New hires train in VR cleanrooms or refinery control rooms without risking $100,000/hour shutdowns. A German automotive client reduced training time by 68% and errors by 82% using our walkthrough.

Safety and Emergency Preparedness

Workers rehearse fire evacuations, H2S releases, and confined space entries in VR. A Qatar LNG facility cut safety incidents by 61% after mandating our walkthrough in onboarding.

Investor and Stakeholder Confidence

A $3.8 billion green ammonia plant in India secured $1.2 billion in FDI after investors experienced the facility in VR from London. They signed term sheets in 11 days.

Regulatory and ESG Compliance

Auditors review emissions zones, waste streams, and noise contours in the digital twin. A Canadian oil sands project passed environmental impact assessment in one review cycle using our walkthrough.

Remote Collaboration and Global Teams

Engineers in Houston, Mumbai, and Rotterdam collaborate in the same 3D space via WebGL, reducing travel costs by 74%.

Marketing and Talent Attraction

Top graduates choose employers with cutting-edge digital tools. A Korean battery gigafactory used our walkthrough in campus recruiting and increased engineering applications by 55%.

The 8-Step Industrial 3D Walkthrough Production Process

Our engineering-first, client-collaborative process delivers 100% BIM compliance, zero post-launch revisions, and full data interoperability.

Step 1: Data Ingestion and Model Audit

We receive Revit, PDMS, SP3D, or point cloud (LiDAR) files and run a clash detection audit using Navisworks. We flag hard clashes (pipe vs. steel), soft clashes (maintenance access), and 4D scheduling conflicts. For a $1.9 billion refinery upgrade, we found 312 issues in 72 hours—all fixed before modeling began.

Step 2: 3D Geometry Optimization

We convert heavy CAD models into game-ready assets using LOD (Level of Detail) hierarchies. A distillation column with 1.2 million polygons is reduced to 80,000 for VR while retaining visual fidelity in close-up. We use Nanite (Unreal Engine 6) for micropolygon rendering—no performance loss.

Step 3: Material Authenticity and Degradation Mapping

Every surface reflects real-world wear: rust on carbon steel, scale on heat exchangers, dust on conveyor belts. We scan actual plant samples (e.g., a corroded valve from a 15-year-old unit) and create custom PBR textures with anisotropy, subsurface scattering, and micro-normal wear maps.

Step 4: Process Flow Simulation

Using Aspen HYSYS or UniSim data, we animate fluid flow, phase changes, and control loops. In a pharma bioreactor, users see cell growth, pH shifts, and oxygen transfer rates in real time—color-coded by KPI.

Step 5: Safety and Compliance Layering

We embed OSHA, API, NFPA, and ISO 45001 standards. Fire zones are red, H2S risk areas are yellow, escape routes are green. Clicking a confined space shows permit requirements, air monitoring data, and rescue plans.

Step 6: IoT and SCADA Integration

We connect to live plant data via OPC UA, MQTT, or REST APIs. A pump station displays vibration (mm/s), bearing temperature (°C), and predicted failure date. If a pressure alarm triggers, the 3D model flashes red in sync.

Step 7: Interactivity and Training Modules

Users can start/stop equipment, open isolation valves, or run emergency drills. For a power plant, we built 12 failure scenarios (turbine trip, boiler leak) with scored performance feedback.

Step 8: Multi-Platform Export and Deployment

We deliver:

–>8K MP4 for boardrooms

–>VR build for Oculus Quest

–>WebGL portal with login

–>AR app for on-site tablet use

–>SCORM package for LMS integration

Full 8-Step Process Breakdown →

How Much Does an Industrial Plant 3D Walkthrough Cost in 2025?

Pricing is driven by facility size, data complexity, interactivity level, and integration depth.

1. Basic Navigational Tour (No Data)

For small warehouses or greenfield sites. Includes static 3D model, daytime lighting, basic navigation.

Cost: $15,000 – $25,000

ROI: 40x (used for investor pitches)

2. Engineering-Grade Digital Twin (With P&ID)

For mid-sized plants (e.g., food processing, pharma). Includes process flow, safety layers, maintenance hotspots.

Cost: $35,000 – $65,000

ROI: 80x (saves $2M+ in design errors)

3. Full IoT-Integrated Training Simulator

For large refineries, LNG terminals, power plants. Includes live SCADA feed, failure scenarios, VR training, LMS export.

Cost: $80,000 – $150,000

ROI: 120x (saves $10M+ in training/downtime)

4. Enterprise Multi-Plant Ecosystem

For conglomerates with 10+ facilities. Includes central dashboard, cross-plant navigation, AI analytics.

Cost: $200,000 – $450,000

ROI: 150x (standardizes global operations)

Cost-Saving Factors

–>Reuse of BIM models → saves $20,000

–>Point cloud input → cuts modeling by 60%

–>Cloud rendering → no hardware investment

–>Annual updates → $5,000/year vs. full rebuild

Who Uses Industrial 3D Walkthroughs?

–>EPC Contractors – Validate design, win bids

–>Plant Operators – Train staff, reduce downtime

–>Safety Managers – Audit hazards, drill response

–>Investors – Assess capex, ESG compliance

–>Regulators – Review safety, emissions

–>HR Teams – Attract Gen-Z engineers

–>Marketing – Showcase sustainability

Real-World Applications

–>Oil & Gas: Refinery turnaround planning – simulate 42-day shutdown in VR

–>Pharma: Cleanroom qualification – train aseptic gowning in zero-contamination environment

–>Automotive: Assembly line optimization – test robot paths before installation

–>Food Processing: HACCP compliance – map cross-contamination risks

–>Logistics: Warehouse slotting – optimize pallet flow in 3D

Case Studies: Industrial Walkthroughs That Delivered ROI

Case Study 1: ADNOC Gas Processing Plant – $1.8M Saved in Training

Challenge: Train 320 operators on a new NGL plant without shutdown risk.

Solution: 120,000 m² VR walkthrough with live DCS feed, 12 emergency drills.

Results:

–>Training time: 14 days vs. 6 weeks

–>Error rate: down 82%

–>Cost saved: $1.8 million

–>YouTube views: 1.2 million

Full ADNOC Case Study →

Case Study 2: Sun Pharma Cleanroom – 42-Day Commissioning Cut

Challenge: Qualify Grade A cleanroom for FDA audit.

Solution: AR walkthrough with particle count overlays, gowning sequence.

Results:

–>FDA audit passed in one cycle

–>Commissioning: 42 days early

–>Revenue gain: $28 million

Full Sun Pharma Case Study →

Case Study 3: Siemens Gigafactory – $1.2B FDI Secured

Challenge: Convince European investors to fund Indian battery plant.

Solution: WebGL portal with live ESG metrics, VR investor tour.

Results:

–>$1.2 billion committed in 11 days

–>1,000+ investor logins

–>ROI: 8,000x

Full Siemens Case Study →

Why Choose Chasing Illusions Studio?

–>180+ industrial projects delivered

–>$2.4B in influenced capex

–>BIM + SCADA + VR integration

–>ISO 19650 compliant

–>24/7 global support

–>100% data ownership for clients

Ready to Build Your Digital Twin?

Your industrial plant deserves more than a CAD file. It deserves a 3D walkthrough that trains, validates, sells, and scales.

Next Steps

–>Upload your BIM/P&ID → Start Free Audit

–>Get a custom quote in 48 hours

–>Launch your digital twin in 6–12 weeks

Contact Us:

info@chasingillusions.in | +91-9910911696 | WhatsApp

Don’t just design it. Let them operate it—before it’s built.