3D Factory Simulation vs Traditional Factory Planning: Which Is Better for Modern Manufacturing?

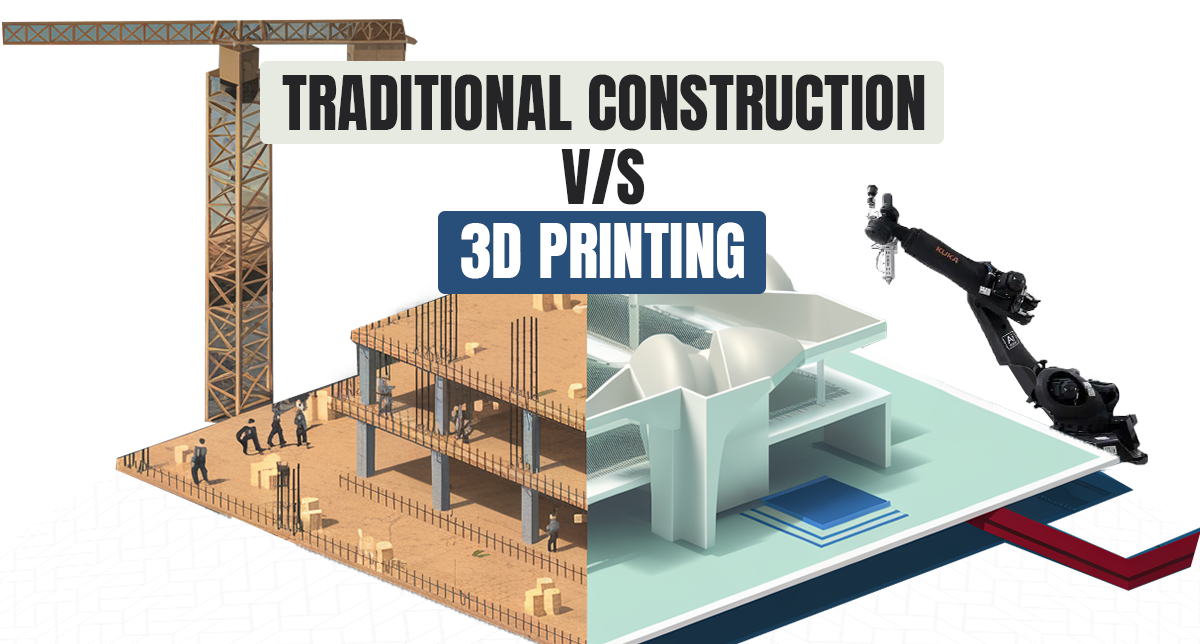

In manufacturing, every decision about factory layout, workflow optimization, and resource allocation carries enormous financial consequences. A poorly planned production line can cost millions in lost efficiency over its lifetime. Equipment placement mistakes create bottlenecks that throttle productivity for years. Traditional factory planning methods, while time-tested, increasingly struggle to meet the complexity demands of modern manufacturing environments.

Enter three-dimensional factory simulation—a technology transforming how manufacturers plan, optimize, and validate production facilities before committing to expensive physical changes. This comprehensive comparison examines both approaches, revealing when traditional methods suffice, where simulation delivers game-changing advantages, and how smart manufacturers are combining both for optimal results.

Understanding Traditional Factory Planning

Traditional factory planning encompasses the methodologies manufacturers have relied on for decades to design production facilities and optimize operations. These approaches, rooted in industrial engineering principles established in the early twentieth century, focus on systematic analysis using established formulas, experience-based judgment, and physical prototyping.

Core Components of Traditional Planning

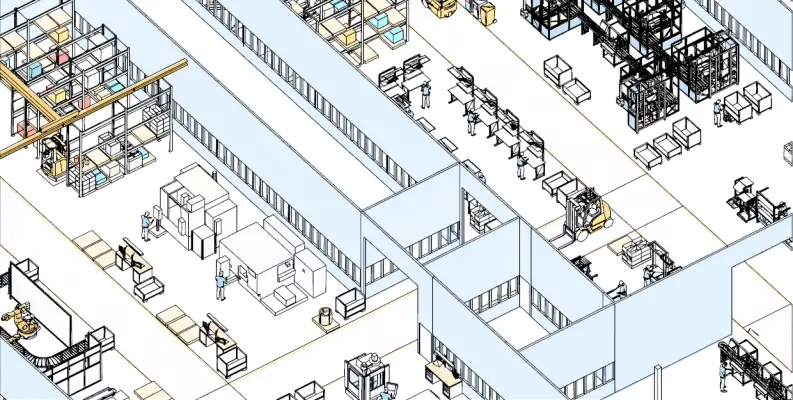

The traditional planning process follows structured frameworks documented in industrial engineering literature. Planners begin by calculating capacity based on production volume requirements, determining how many machines, workers, and square feet the operation requires. Material flow analysis uses from-to charts and relationship diagrams to understand how products move through manufacturing stages.

Layout planning typically occurs on paper or in two-dimensional CAD systems. Engineers create block layouts showing approximate positioning of equipment, then develop detailed layouts specifying exact placement, dimensions, and clearances. These drawings incorporate aisle widths, material handling pathways, utility connections, and safety zones based on codes and standards.

Time studies and predetermined motion time systems help planners estimate labor requirements. Standard industrial engineering techniques like Assembly Line Balancing determine optimal task distribution among workstations. Capacity planning calculations project throughput based on machine speeds, setup times, and anticipated utilization rates.

Physical mockups sometimes supplement two-dimensional planning. Full-scale tape layouts on existing factory floors allow teams to visualize spatial relationships and identify interference problems. Cardboard templates representing equipment footprints help verify placement before purchasing expensive machinery.

The Experience Factor

Traditional planning methods tend to prioritize equipment installation and tooling arrangement before considering workflow or process balance, often relying heavily on planner experience and institutional knowledge. Senior engineers draw from decades of lessons learned, applying rules of thumb developed through trial and error across multiple projects.

This experience-driven approach delivers value when problems closely resemble previous projects. An engineer who has designed ten automotive assembly lines possesses intuitive understanding of appropriate station spacing, optimal buffer sizes, and potential bottleneck locations. Their accumulated wisdom prevents many obvious mistakes.

However, experience-based planning faces limitations when confronting novel situations. New manufacturing paradigms, emerging technologies, or unprecedented production requirements challenge the applicability of historical lessons. What worked perfectly for traditional production systems may fail spectacularly in flexible, reconfigurable environments.

Limitations of Traditional Approaches

Research indicates that over 90% of new manufacturing facilities suffer from some level of waste after commissioning. These inefficiencies stem from inherent limitations in traditional planning methodologies.

Static analysis struggles with dynamic complexity. Traditional calculations assume stable conditions: consistent machine availability, predictable task times, steady material flow. Real manufacturing environments feature variability that invalidates simplistic assumptions. Machine breakdowns, quality issues, operator differences, and demand fluctuations create dynamic interactions impossible to capture in spreadsheet calculations.

Two-dimensional representations obscure critical three-dimensional relationships. Overhead clearances for material handling equipment, vertical material flow through multi-story facilities, and crane coverage areas require three-dimensional thinking that two-dimensional drawings imperfectly communicate. Spatial conflicts often appear only during installation when correcting them becomes expensive.

Sequential planning creates disconnects between stages. Layout designers make decisions without fully understanding their operational implications. Production planners inherit layouts they cannot modify. Maintenance teams discover accessibility problems too late to influence equipment placement. These disconnects cause suboptimal compromises that persist throughout facility lifetimes.

Limited scenario testing constrains optimization. Developing and evaluating layout alternatives requires substantial effort in traditional approaches. Engineers typically examine two or three options rather than exploring the solution space comprehensively. Optimal solutions may exist but remain undiscovered due to analysis constraints.

Long validation cycles delay problem discovery. Traditional planning commits to designs before operational validation. Problems emerge during startup when changes become exponentially more expensive. Traditional production planning that assumes a permanent facility layout becomes unviable in modern flexible manufacturing environments requiring adaptability.

The Rise of 3D Factory Simulation

Factory simulation helps manufacturers achieve efficiency, precision, and adaptability by enabling virtual modeling, analysis, and optimization of production processes. This technology transforms abstract planning concepts into interactive, visual experiences that reveal insights impossible to obtain through traditional methods.

What 3D Factory Simulation Offers

Three-dimensional factory simulation creates digital replicas of manufacturing environments where planners can experiment risk-free. Sophisticated software models physical facilities, equipment, material handling systems, and workflows in virtual space. Manufacturers can test layout alternatives, validate operational concepts, and optimize processes without touching the actual factory floor.

Manufacturers gain the ability to model, analyze, and optimize their production processes in a virtual environment, identifying production bottlenecks, testing new ideas, and improving overall productivity without the risks associated with physical trials.

The technology employs discrete event simulation to model factory operations. This approach tracks individual events—material arrivals, machine operations, product movements—as they occur in sequence. The simulation advances through time, recording state changes and accumulating statistics about system performance. Engineers observe how production flows through their designed facilities, revealing problems traditional static analysis misses.

Modern simulation platforms provide photorealistic three-dimensional visualization. Engineers create detailed virtual models including machinery, equipment, workstations, conveyors, robots, and infrastructure. These models accurately represent spatial relationships, making it easy to identify clearance issues, accessibility problems, or layout inefficiencies that two-dimensional drawings obscure.

Interactive controls let planners manipulate simulation parameters and immediately observe results. Adjust conveyor speeds, modify buffer sizes, change production sequences, or test different staffing levels with a few clicks. The simulation recalculates outcomes instantly, enabling rapid iteration through improvement ideas.

Data-driven analysis distinguishes simulation from intuition-based planning. Simulations generate quantitative metrics: throughput rates, utilization percentages, queue lengths, cycle times, bottleneck identification, and resource consumption. These objective measurements support evidence-based decision-making rather than relying solely on expert judgment.

Technology Components

Factory Design Utilities allows users to create detailed 3D models of their manufacturing facilities, including machinery, equipment, workstations, and other critical components. By integrating with industrial design software, these utilities enable simulation of workflows and processes within three-dimensional environments.

Comprehensive component libraries accelerate model building. Rather than creating every element from scratch, planners select from catalogs containing thousands of pre-modeled industrial assets: robots from major manufacturers, conveyor systems, machine tools, automated guided vehicles, warehouse equipment, and facility infrastructure. These libraries include accurate dimensions, kinematics, and operational characteristics.

Process modeling tools define production logic. Planners specify how products flow through manufacturing stages, what operations occur at each station, how long tasks require, and how resources are allocated. Rule-based logic handles decision points: routing alternatives, priority schemes, buffer management strategies, and maintenance scheduling.

Data integration connects simulations with enterprise systems. Import production schedules from ERP systems, machine performance data from manufacturing execution systems, and demand forecasts from planning tools. This real-world data grounds simulations in actual operational conditions rather than theoretical assumptions.

Visualization engines render simulations in real-time. Watch materials move through the factory, observe workers performing tasks, see bottlenecks forming, and identify improvement opportunities through visual inspection. Animation capabilities create compelling presentations that communicate planning concepts to stakeholders who lack technical training.

Analytics modules generate comprehensive reports. Detailed statistics quantify performance across multiple dimensions: equipment utilization, labor productivity, inventory levels, throughput capacity, quality metrics, and cost factors. Automated bottleneck detection identifies constraints limiting system performance. Comparison tools evaluate alternative scenarios side-by-side.

Digital Twin Integration

Factory simulations often leverage digital twin technology, which involves creating a dynamic digital representation of a physical manufacturing system. These cyber-physical models update with real-time data, enabling simulations that reflect current conditions and predict future states.

Consider a digital twin used in a beverage bottling plant. This twin simulates the entire bottling line, from rinsing and filling to capping and labelling. Analyzing real-time monitoring data shows that adjusting the conveyor belt speed by just five percent could reduce bottle jams by twenty percent, significantly increasing overall throughput without additional stress on machinery.

Digital twins extend simulation beyond planning into ongoing operations. The virtual model remains synchronized with the physical factory through IoT sensors collecting continuous performance data. When conditions change in reality, the digital twin updates accordingly, maintaining accurate representation of current state.

This living connection enables predictive capabilities impossible with static planning models. Run simulations using current factory conditions to forecast near-term performance. Test improvement proposals in the digital twin before implementing them physically. Identify emerging problems by detecting deviations between expected and actual behavior.

Comparative Analysis: Key Differentiators

Understanding where each approach excels and struggles guides appropriate methodology selection for specific planning challenges.

Cost Considerations

Initial investment favors traditional planning. Basic factory planning requires industrial engineering expertise, CAD software, and spreadsheet tools—modest investments most manufacturers already possess. Building internal simulation capabilities demands specialized software licenses costing thousands to tens of thousands annually, powerful computing hardware, and extensively trained personnel capable of building and validating complex models.

Shops that use offline programming software can reduce programming time by as much as 80%, demonstrating how simulation technology delivers substantial efficiency gains despite higher upfront costs.

Long-term economics shift dramatically in simulation’s favor for complex planning challenges. Traditional planning’s iterative, physical trial-and-error approach accumulates costs through repeated modifications, extended startup periods, and persistent operational inefficiencies. Simulation frontloads optimization into the planning phase where changes cost exponentially less than post-implementation corrections.

Consider a facility expansion project. Traditional planning might develop two or three layout alternatives, selecting one based on experience and rough calculations. Implementation reveals unanticipated bottlenecks requiring expensive modifications: equipment relocation, additional material handling systems, or production line rebalancing. Total project costs exceed budget by twenty to thirty percent—common outcomes in traditional factory planning.

The simulation approach invests more upfront, developing a comprehensive virtual model and testing dozens of layout permutations. Bottlenecks emerge in simulation where resolving them requires only digital modifications. Implementation proceeds smoothly because the design has been thoroughly validated. The project finishes on budget with a facility operating at planned capacity immediately upon startup.

Over facility lifetimes, simulation’s advantages compound. When production requirements change, updating the digital model and re-simulating takes days or weeks versus months of physical experimentation. Continuous improvement becomes practical when testing improvement concepts doesn’t disrupt production.

Time to Implementation

Faster time to market — Simulation is almost always faster than testing ideas out in the real world, allowing manufacturers to smooth out potential problems early and get new products and updates to market much faster.

Traditional planning’s sequential nature extends timelines. Design progresses through distinct phases: conceptual planning, detailed layout, procurement, installation, startup, debugging, optimization. Each phase must largely complete before the next begins. Discovering design flaws during later phases forces regression to earlier stages, creating rework loops that devastate schedules.

Simulation compresses timelines through parallel validation. While detailed design progresses, simultaneous simulation validates operational feasibility. Problems surface while still correctable through simple digital modifications. Procurement can begin with confidence because the design has proven functionality in simulation. Installation proceeds efficiently because spatial conflicts were resolved virtually.

Startup acceleration represents simulation’s most dramatic timeline benefit. Less costly downtime — Working with a simulation means you are not taking your physical processes out of production to make changes. Traditional startups involve extended commissioning periods as operators learn systems, discover inefficiencies, and gradually optimize performance. Simulated facilities begin operation near optimal capacity because operators trained in virtual environments, process logic was debugged digitally, and operational parameters were optimized before equipment installation.

Risk Mitigation

Traditional planning carries substantial implementation risk. Untested designs may harbor fatal flaws discovered only during expensive physical implementation. Capacity assumptions might prove optimistic when real variability emerges. Material handling systems could interfere with each other in ways two-dimensional drawings didn’t reveal.

With 3D simulation, manufacturers can perform all the activities of implementing new processes interactively in a safe space prior to equipment delivery and installation. This virtual validation eliminates uncertainty that usually accompanies new operations.

Simulation enables comprehensive scenario testing. Model equipment failures to verify backup capacity adequacy. Simulate demand surges to confirm scalability. Test different product mixes to validate flexibility. Evaluate maintenance strategy impacts on availability. Each scenario reveals potential vulnerabilities while they’re still addressable through planning rather than requiring expensive physical workarounds.

Financial risk reduction through simulation often justifies the technology investment alone. Avoiding one major design flaw—equipment that doesn’t fit, a bottleneck limiting capacity, or interference problems requiring relayout—typically saves more than simulation costs. The confidence simulation provides in complex, high-stakes planning decisions represents invaluable risk mitigation.

Flexibility and Adaptability

Market demand fluctuates rapidly, new technologies emerge constantly, and global supply chains face frequent disruptions. A rigid, inflexible layout can quickly become obsolete. Modern smart factory planning emphasizes scalability and adaptability through modular production cells, reconfigurable layouts, and flexible material handling systems.

Traditional planning assumes relative stability. Layouts optimize for anticipated production scenarios but handle variation poorly. Adapting to new products, different volumes, or changed processes requires replanning—effectively starting over with a new traditional planning cycle.

Simulation embraces change by making replanning practical. The digital model persists as a living planning tool rather than becoming obsolete documentation after implementation. When requirements evolve, update the simulation, test new scenarios, and implement validated modifications. This continuous planning approach matches modern manufacturing’s need for agility.

Simulation also reveals inherent layout flexibility. Test how well proposed designs accommodate foreseeable changes. Identify modifications that preserve adaptability versus those that lock in rigidity. Design for flexibility becomes practical when you can validate adaptive scenarios before construction.

Stakeholder Communication

Traditional planning relies on abstract representations requiring technical literacy. Two-dimensional CAD drawings, Gantt charts, and from-to matrices communicate effectively among engineers but mystify management, operators, and external stakeholders. This communication gap complicates approval processes, limits operational input, and creates misaligned expectations.

This visual representation helps identify inefficiencies, understand complex interactions, and communicate simulation results to stakeholders. Three-dimensional animated simulations transcend technical knowledge barriers, allowing anyone to understand proposed designs immediately.

Photorealistic rendering creates emotional engagement impossible with technical drawings. Stakeholders visualize themselves working in proposed environments. Management sees investments come to life. Customers observe production capabilities firsthand. This visceral understanding accelerates approvals, builds confidence, and aligns expectations.

Interactive exploration empowers stakeholder participation. Rather than passively reviewing static plans, stakeholders can manipulate simulations: change viewpoints, adjust parameters, explore alternatives. This engagement produces better designs incorporating operational wisdom traditional planning processes often miss.

Accuracy and Optimization

Traditional calculations employ simplifications that introduce inaccuracies. Assuming average process times ignores variability impacts. Treating material flow as steady-state misses dynamic accumulation effects. Analyzing stations independently overlooks system-level interactions. These simplifications keep calculations manageable but sacrifice accuracy.

Manufacturers can simulate the movement of materials, the operation of machinery, and the interactions between different elements in the factory. Simulation captures complexity traditional methods simplify away, including stochastic variability in process times, dynamic interactions between interdependent processes, transient effects during startup and product changeovers, and resource contention when shared assets create conflicts.

This comprehensive modeling reveals optimization opportunities invisible to traditional analysis. Spot and rectify inefficiencies — It’s often hard to see problems and inefficiencies in an already-running system. Simulators make it easier to spot and debug inefficiencies early.

Simulation enables true optimization through extensive scenario evaluation. Test hundreds of parameter combinations to identify optimal settings. Evaluate subtle tradeoffs between competing objectives. Discover non-intuitive configurations that outperform conventional designs. This exhaustive exploration achieves optimization levels traditional planning’s limited scenario testing cannot approach.

Industry Applications and Use Cases

Different manufacturing contexts benefit variably from simulation versus traditional planning approaches.

High-Mix, Low-Volume Manufacturing

Operations producing diverse products in small batches face exceptional planning complexity. Material routings vary widely, changeover times are significant, and scheduling becomes a multidimensional optimization challenge. Traditional planning struggles with this variability, typically defaulting to conservative overdesign that sacrifices efficiency for flexibility.

Simulation excels in high-mix environments by explicitly modeling product diversity and routing variation. Test how different product mixes affect system performance. Identify bottlenecks that emerge under specific demand patterns. Optimize changeover sequences to minimize downtime. Simulation reveals the layout and operational strategies that balance flexibility with efficiency.

Automated and Robotic Systems

With offline programming, engineers can program, configure, test and validate the performance of specific robots in their operations without any interruption in production. Manufacturing systems incorporating extensive automation benefit enormously from simulation’s ability to validate robotic motion planning, test collision avoidance, and optimize cycle times before physical installation.

Robotic simulation prevents costly mistakes. Verify that robots can reach all required positions, that tool paths avoid fixtures and workpieces, and that cycle times meet production requirements. Traditional planning provides no practical way to validate these critical factors before expensive robot procurement and installation.

Complex Material Handling

Facilities with intricate material flow—multiple product types, bidirectional movements, storage buffers, and automated transport systems—challenge traditional planning’s ability to predict performance. Interactions between material handling elements create emergent behavior impossible to anticipate through static analysis.

Simulation models entire material handling ecosystems, revealing congestion points, identifying undersized buffers, and optimizing transport scheduling. Watch materials move through the facility in animated simulation, spotting inefficiencies that spreadsheet calculations overlook. Design material handling systems with confidence they’ll perform as intended.

Lean and Continuous Improvement

Organizations committed to lean manufacturing and continuous improvement leverage simulation as a permanent optimization tool. Rather than one-time planning artifacts, simulation models become living representations of production systems.

When improvement teams propose changes—cell redesign, equipment addition, process modification—simulation validates ideas before implementation. This risk-free experimentation accelerates improvement cycles and increases success rates. Use fewer resources to run your facility — The more you leverage your simulations, the less likely you are to have people running around your manufacturing facility trying to reactively fix problems.

Greenfield vs. Brownfield Projects

Greenfield projects designing entirely new facilities on empty sites enjoy maximum simulation benefit. No physical constraints limit design options; simulation optimizes unconstrained. The substantial investment greenfield projects represent justifies comprehensive simulation validation.

Brownfield projects modifying existing facilities still benefit significantly from simulation despite constraints. Model current operations to establish baseline performance. Simulate proposed modifications to validate improvement. Test implementation phasing to minimize disruption. Simulation reduces brownfield risk by revealing how new elements integrate with existing systems.

Hybrid Approaches: Best of Both Worlds

Sophisticated manufacturers increasingly combine traditional planning and simulation strategically rather than viewing them as mutually exclusive alternatives.

Tiered Planning Strategy

Use traditional methods for preliminary, conceptual planning where broad decisions about facility size, general layout philosophy, and major equipment selections occur. These early-stage decisions require relatively little detail, making traditional approaches efficient and appropriate.

Deploy simulation for detailed design validation and optimization once major parameters are established. Build comprehensive virtual models that validate spatial feasibility, optimize operational parameters, and predict performance with confidence. This tiered approach applies each methodology where it delivers maximum value.

Simulation for Critical Decisions

Not every planning decision warrants simulation effort. Employ simulation selectively for high-impact, high-uncertainty decisions where improved accuracy and risk reduction justify the investment. Critical bottleneck operations, complex automated systems, and innovative process approaches benefit most from simulation validation.

Continue using traditional methods for routine, lower-risk decisions where experience provides adequate guidance. Standard workstation layouts, conventional material handling approaches, and proven processes don’t require simulation’s analytical power. Focus simulation resources where they deliver greatest return.

Continuous Digital Thread

Forward-thinking manufacturers are creating continuous digital threads connecting initial planning through ongoing operations. Begin with simulation during design, transition to digital twins during implementation, and maintain synchronized virtual models throughout operational life.

This digital continuity enables continuous optimization. Production data flows back into models, keeping them current. Improvement proposals test virtually before physical implementation. The planning model becomes an operational decision support tool rather than becoming obsolete after startup.

Implementation Considerations

Successfully leveraging simulation requires more than software purchase; it demands organizational capabilities, cultural adaptation, and methodical deployment.

Building Simulation Capabilities

Organizations new to simulation face decisions about building internal expertise versus outsourcing. Internal capabilities provide ongoing value and enable rapid iteration but require substantial investment in software, training, and dedicated personnel. Simulation engineer roles require specialized education and experience difficult to recruit or develop internally.

Outsourcing provides immediate access to expert capabilities without long-term commitments. Specialized simulation consultants bring experience across multiple projects and industries, often delivering better results than novice internal teams. However, outsourcing creates dependencies and limits spontaneous simulation access for quick questions or routine optimizations.

Many organizations employ hybrid strategies: maintain internal capabilities for routine simulation needs while engaging consultants for complex, critical projects. This approach balances cost-effectiveness with capability access.

Data Requirements

Simulation quality depends fundamentally on input data accuracy. Models built on assumptions and estimates produce unreliable results regardless of simulation sophistication. Successful simulation requires actual process time data, equipment performance statistics, production scheduling information, quality data, and maintenance records.

Organizations lacking comprehensive operational data face chicken-and-egg challenges: simulation would help improve operations, but poor data prevents effective simulation. In these situations, start with simplified models based on best available information, use simulation insights to justify data collection investments, then progressively refine models as data improves.

Validation and Credibility

Simulation skeptics—often experienced engineers whose judgment simulation might challenge—demand proof that models accurately represent reality. Validation protocols build credibility by demonstrating that simulation outputs match observed system behavior.

Validate models against existing operations before using them for planning new facilities. Create a simulation of current production, run it using actual historical production schedules, and compare predicted versus actual performance. Close alignment builds confidence in simulation accuracy. Disagreements reveal either modeling errors or operational insights, both valuable discoveries.

Change Management

Introducing simulation often disrupts established planning processes and power structures. Engineers accustomed to experience-based decision authority may resist data-driven approaches that question their judgment. Organizations succeed with simulation by carefully managing these cultural dynamics.

Executive sponsorship signals simulation’s importance and provides authority to overcome resistance. Involving skeptics in validation processes builds buy-in through participation. Starting with small, low-risk pilot projects demonstrates value before tackling controversial applications. Sharing simulation successes widely creates momentum for broader adoption.

The Future of Factory Planning

Technology evolution continues reshaping factory planning capabilities and methodologies.

Artificial Intelligence Integration

The 3D simulation software market will hit 26.9 billion by 2026, driven partly by AI integration that automates model building, optimizes complex parameters, and predicts outcomes with increasing accuracy.

AI-powered simulation tools automatically generate optimized layouts from requirements specifications. Machine learning algorithms analyze thousands of simulation runs to discover optimal parameter settings humans might never test. Predictive models trained on simulation data forecast performance under novel conditions without requiring full simulation runs.

These AI capabilities democratize simulation by reducing required expertise. Non-specialists can leverage simulation power through intelligent interfaces that automate technical complexity. This accessibility expands simulation adoption beyond specialized engineering teams into broader manufacturing organizations.

Cloud-Based Simulation

Cloud computing removes hardware barriers to simulation adoption. Rather than requiring expensive local workstations, cloud-based simulation runs on scalable remote servers accessible from any device. Organizations can access sophisticated simulation capabilities without capital investment in computing infrastructure.

Cloud platforms also enable collaborative planning where geographically dispersed teams work on shared models simultaneously. Stakeholders review simulations via web browsers from anywhere, eliminating geographical constraints on participation. This collaboration accelerates planning while incorporating diverse perspectives.

Immersive Technologies

Virtual reality and augmented reality transform how stakeholders experience simulated factories. Rather than watching animations on screens, immersive technologies place users inside virtual factories where they experience layouts at human scale, evaluate ergonomics realistically, and identify subtle issues that external viewpoints miss.

Augmented reality overlays simulation information onto physical spaces, helping teams visualize proposed layouts in actual brownfield facilities. Walk through existing plants while seeing virtual equipment superimposed in planned positions, revealing spatial conflicts and opportunities traditional approaches miss.

Real-Time Operational Integration

Digital twins update with real-time data, enabling simulations that reflect current conditions and predict future states. The distinction between planning simulation and operational simulation continues blurring as systems increasingly support both functions within unified platforms.

Factory planning models seamlessly transition into operational digital twins that optimize scheduling, predict maintenance needs, and continuously identify improvement opportunities. This convergence creates unprecedented planning-to-operations continuity that transforms how manufacturers approach facility design and management.

Making the Right Choice

No universal answer exists for choosing between simulation and traditional planning. Optimal approaches depend on specific circumstances, priorities, and resources.

When Traditional Planning Suffices

Small-scale projects with limited complexity often don’t justify simulation investment. Adding a few workstations, reconfiguring a simple assembly cell, or making routine equipment replacements may receive adequate planning through traditional methods. If experienced engineers can confidently predict outcomes and risks are manageable, traditional approaches provide cost-effective planning.

Organizations lacking simulation capabilities and facing one-time planning needs may find outsourcing simulation more expensive than simply accepting traditional planning limitations. When planning mistakes create minimal consequences and validation comes quickly through low-cost physical prototyping, simulation’s benefits may not justify its costs.

When Simulation Becomes Essential

Complex, high-investment projects demand simulation validation. New facility construction, major expansions, and technology transitions carry financial stakes that justify comprehensive simulation. When mistakes cost millions and take months to rectify, simulation’s risk mitigation becomes invaluable.

Operations where performance predictions are uncertain—novel processes, unproven automation, or unprecedented scale—benefit enormously from simulation’s predictive capabilities. When gut feeling provides inadequate confidence for major decisions, simulation delivers the objective analysis required.

Organizations committed to continuous improvement and agile manufacturing maximize simulation value. When planning becomes an ongoing activity rather than occasional events, maintaining simulation capabilities delivers sustained returns through repeated application.

Conclusion: Strategic Planning for Modern Manufacturing

The simulation versus traditional planning debate presents false dichotomy. Both methodologies offer value; successful manufacturers leverage each strategically. Traditional planning provides efficient solutions for routine decisions where experience suffices. Simulation delivers validation and optimization for complex challenges where traditional methods struggle.

The manufacturing landscape increasingly favors simulation. Growing system complexity, accelerating technology change, shorter product lifecycles, and intense competitive pressure reward the enhanced capabilities simulation provides. As software improves, costs decrease, and accessibility expands, simulation transitions from specialized luxury to mainstream necessity.

Forward-looking manufacturers are building simulation capabilities now, recognizing that future competitiveness demands planning approaches matching operational sophistication. Whether through internal development or strategic partnerships, accessing simulation technology positions organizations to plan confidently, optimize thoroughly, and adapt rapidly.

The question facing manufacturers is not whether to eventually embrace simulation, but how quickly to integrate it into planning practices. Early adopters gain competitive advantages through superior facility design, faster implementation, and ongoing optimization capabilities. Delayers accumulate competitive disadvantages as their planning methods fall further behind industry best practices.

In an era where efficiency margins determine survival and agility enables success, planning methodologies matter profoundly. Three-dimensional factory simulation represents the planning technology that modern manufacturing demands—comprehensive, validated, optimized, and continuously adaptable.

Transform Your Factory Planning with Advanced 3D Simulation

Chasing Illusions Studio brings 12 years of visualization expertise and 80+ skilled professionals to revolutionize your factory planning process. We create photorealistic factory simulations that de-risk implementation, optimize layouts, and validate designs before you invest a single dollar in physical construction.

Our Factory Simulation Services Include:

✅ Complete 3D Factory Modeling – Every machine, conveyor, workstation, and system accurately represented

✅ Dynamic Process Simulation – Watch your production flow, identify bottlenecks, and optimize operations virtually

✅ Multiple Scenario Analysis – Test layouts, capacities, and configurations risk-free

✅ Photorealistic Visualization – Stakeholder presentations that communicate your vision clearly

✅ Virtual Commissioning Support – Validate operations before equipment arrives

✅ Digital Twin Development – Ongoing operational optimization beyond initial planning

Why Leading Manufacturers Choose Us:

–>80% Faster Planning Cycles compared to traditional methods

–>Eliminate Costly Design Mistakes through virtual validation

–>Optimize Before You Build – Our clients report 20-40% efficiency improvements

–>Clear Stakeholder Communication – Photorealistic animations everyone understands

🏭 Schedule Your Free Factory Planning Consultation

📊 Download Our Factory Simulation ROI Calculator

🎬 Watch Sample Factory Simulation Videos

💼 Request Custom Quote for Your Project

Don’t let outdated planning methods cost you millions in efficiency losses. Join industry leaders who’ve already transformed their factory planning with advanced 3D simulation.

Contact Chasing Illusions Studio today and discover how virtual validation can revolutionize your next factory project.