The Hidden Costs of 3D Factory Plant Walkthrough Projects

In the UAE’s thriving industrial landscape, 3D factory plant walkthrough projects are transforming how businesses in oil and gas, petrochemicals, and manufacturing visualize their facilities. These photorealistic animations, crafted by studios like Chasing Illusions Studio (chasingillusions.com), provide virtual tours of factory layouts, showcasing equipment, workflows, and safety protocols in vivid detail. For UAE companies, particularly those aligned with ADNOC’s rigorous Health, Safety, and Environment (HSE) standards, 3D factory plant walkthrough projects serve multiple purposes, from attracting investors to training workers on hydrogen sulfide (H₂S) safety protocols and planning facility expansions. However, beneath their polished visuals lie hidden costs that can significantly inflate budgets if not anticipated.

This comprehensive guide explores the hidden costs of 3D factory plant walkthrough projects, their implications for UAE businesses, and practical strategies to manage them effectively, ensuring cost-efficiency and project success in 2025.

Understanding 3D Factory Plant Walkthrough Projects

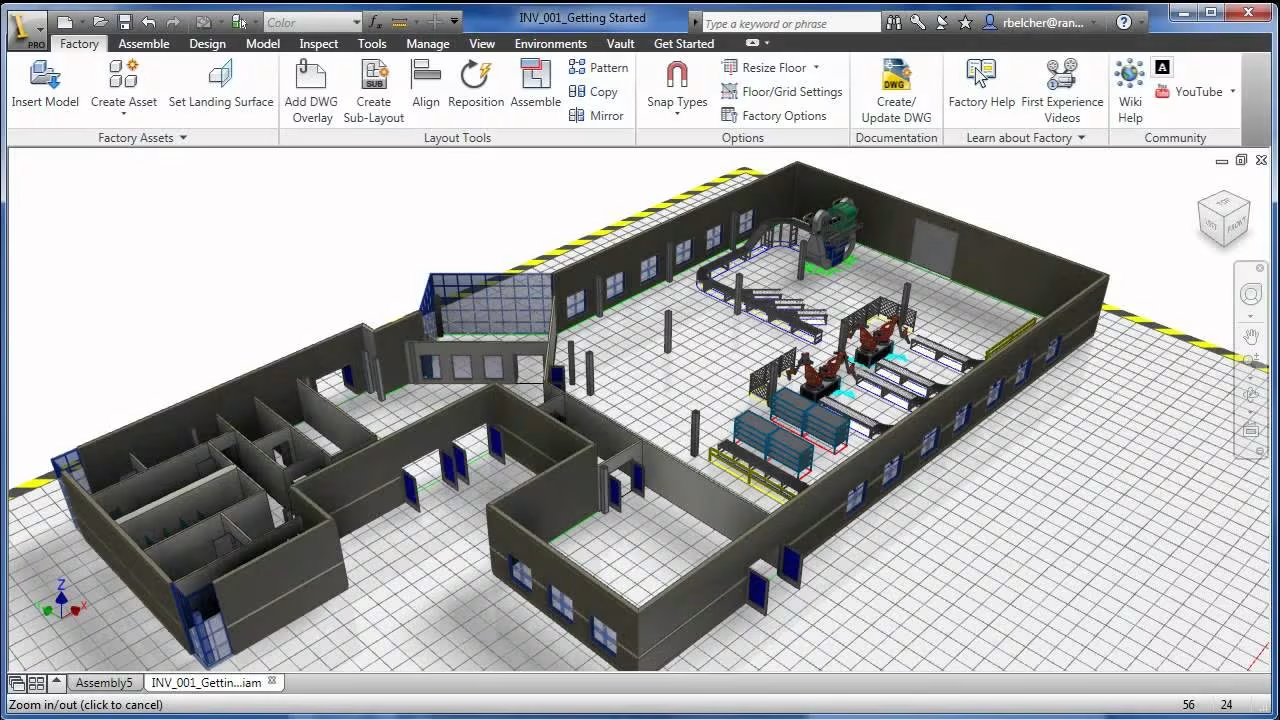

A 3D factory plant walkthrough project leverages advanced 3D animation software such as Blender, Autodesk Maya, or Unreal Engine to create a virtual tour of an industrial facility. These animations simulate a factory’s physical environment, including machinery, pipelines, and safety systems, enabling stakeholders to navigate the space virtually. In the UAE, where industrial giants like ADNOC operate expansive refineries such as Ruwais and Habshan, 3D factory plant walkthrough projects are critical for showcasing facility designs to investors, training workers on OSHA-compliant safety procedures (e.g., 20 ppm H₂S exposure limit per 29 CFR 1910.1000), and planning expansions. The creation process requires collaboration among animators, engineers, and HSE specialists to ensure accuracy and compliance with regulations like NFPA 56 for flammable gas handling.

While these projects offer significant benefits—enhanced engagement, improved training, and informed decision-making—their complexity often leads to unforeseen expenses that can challenge UAE businesses aiming to leverage 3D factory plant walkthrough projects effectively.

Hidden Costs of 3D Factory Plant Walkthrough Projects

Creating a 3D factory plant walkthrough project involves multiple stages, from planning to distribution, each with potential hidden costs that can significantly impact budgets for UAE businesses, particularly in oil and gas or manufacturing. Below, we explore these costs in detail, with examples relevant to the UAE context, using bullet points sparingly to highlight key terms and concepts.

Pre-Production Planning and Research

The foundation of a 3D factory plant walkthrough project lies in thorough pre-production planning to ensure the animation accurately reflects the facility’s design and purpose. This phase requires significant time and expertise, often leading to hidden costs. For a UAE petrochemical plant, planning may involve consulting ADNOC engineers to verify pipeline configurations or HSE officers to incorporate H₂S safety measures. These consultations can cost between AED 5,000 and AED 20,000, depending on the experts’ rates and project complexity.

Site visits to facilities like Ruwais refinery for reference photos or measurements add travel and labor expenses, ranging from AED 2,000 to AED 10,000. Acquiring accurate CAD files or blueprints may require purchasing proprietary data or hiring drafters, costing AED 3,000 to AED 15,000. For example, a UAE manufacturing firm developing a walkthrough for a new production line underestimated the need for on-site surveys, leading to a two-week delay and AED 15,000 in additional costs. Key expenses include:

-

Consulting fees: AED 5,000–20,000 for expert input.

-

Site visits: AED 2,000–10,000 for travel and labor.

-

Data acquisition: AED 3,000–15,000 for CAD files or blueprints.

Without robust planning, projects risk misaligned visuals or non-compliance with ADNOC standards, necessitating costly revisions that can derail timelines and budgets.

High-Quality Modeling and Texturing

Creating photorealistic 3D models of factory components, such as distillation towers or pumps, is central to 3D factory plant walkthrough projects. This process demands skilled artists and detailed textures to achieve realism, but it comes with significant hidden costs. Modeling intricate equipment, like a gas compressor in an ADNOC refinery, can take 50 to 100 hours per asset, costing AED 10,000 to AED 30,000 at UAE rates (AED 100–300/hour). High-resolution textures for metal or concrete often require premium subscriptions to tools like Substance Painter, costing AED 1,000 to AED 3,000 annually. Client feedback requesting changes, such as updating a pump design, can add 10 to 20 hours of rework, costing AED 1,000 to AED 6,000.

For instance, a 3D factory plant walkthrough project for an ADNOC refinery required detailed models of over 50 assets, with revisions doubling initial modeling costs. Key expenses include:

-

Modeling time: AED 10,000–30,000 per asset.

-

Texture subscriptions: AED 1,000–3,000/year.

-

Revisions: AED 1,000–6,000 for client-driven changes.

Underestimating these expenses can lead to low-quality visuals, undermining the project’s effectiveness for training or marketing purposes in UAE industries.

Animation and Rendering Complexity

Animating a seamless 3D factory plant walkthrough project with realistic movements and rendering high-quality visuals is resource-intensive. Animating a 2-minute walkthrough with camera pans and equipment interactions can take 100 to 200 hours, costing AED 10,000 to AED 60,000. Rendering at 4K resolution requires powerful hardware or cloud services like AWS, adding AED 5,000 to AED 20,000 for complex scenes.

Optimizing animations for mobile or VR platforms adds 20 to 50 hours, costing AED 2,000 to AED 15,000. For example, a Dubai manufacturing firm rendering a 3D factory plant walkthrough project for a photorealistic tour faced unexpected cloud rendering costs. Key expenses include:

-

Animation time: AED 10,000–60,000 for a 2-minute walkthrough.

-

Rendering costs: AED 5,000–20,000 for high-resolution output.

-

Optimization: AED 2,000–15,000 for platform compatibility.

Long rendering times or inadequate hardware can delay delivery, affecting marketing deadlines or training schedules in UAE industries.

Multilingual Narration and Accessibility

The UAE’s diverse workforce, including Arabic, English, and Hindi speakers, requires 3D factory plant walkthrough projects to include multilingual narration or subtitles for accessibility. Hiring professional narrators for multiple languages costs AED 1,000 to AED 5,000 per language. Translating scripts into Arabic or Hindi adds AED 500 to AED 2,000 per language.

Syncing subtitles requires 10 to 20 hours of editing, costing AED 1,000 to AED 6,000. For instance, a 3D factory plant walkthrough project for ADNOC’s Habshan facility included Arabic and Hindi narration, doubling audio production costs. Key expenses include:

-

Narration: AED 1,000–5,000 per language.

-

Translation: AED 500–2,000 per language.

-

Subtitles: AED 1,000–6,000 for editing.

Omitting multilingual support can limit audience reach, reducing the project’s impact in the UAE’s multicultural market.

Software and Hardware Investments

Creating 3D factory plant walkthrough projects demands specialized software and hardware, leading to unexpected expenses. Licenses for Autodesk Maya or 3ds Max cost AED 7,000 to AED 15,000 per year per user, while plugins like V-Ray add AED 1,000 to AED 3,000 annually. High-end GPUs (e.g., NVIDIA RTX 4090) or workstations cost AED 10,000 to AED 50,000 for complex rendering. Software updates or hardware repairs add AED 2,000 to AED 10,000 annually. A UAE studio upgrading its hardware to render a 3D factory plant walkthrough project for a petrochemical plant faced unplanned costs. Key expenses include:

-

Software licenses: AED 7,000–15,000/year.

-

Hardware: AED 10,000–50,000 for GPUs/workstations.

-

Maintenance: AED 2,000–10,000/year.

Underestimating these needs can cause rendering bottlenecks, delaying project timelines.

Regulatory Compliance and Customization

In the UAE, 3D factory plant walkthrough projects for oil and gas must comply with ADNOC HSE, OSHA (20 ppm H₂S PEL), and NFPA 56 standards, requiring customization. Hiring HSE consultants to verify safety protocols (e.g., H₂S evacuation routes) costs AED 5,000 to AED 15,000. Adding compliance-specific visuals (e.g., gas detectors, PPE usage) takes 20 to 50 hours, costing AED 2,000 to AED 15,000. Regulatory updates, such as new ADNOC guidelines, may require reworks, adding AED 3,000 to AED 10,000. A 3D factory plant walkthrough project for ADNOC’s Ruwais refinery needed extra animations for OSHA-compliant H₂S measures, increasing costs. Non-compliance risks project rejection or fines, inflating budgets.

Post-Production and Editing

Polishing a 3D factory plant walkthrough project with editing, annotations, and interactive elements adds significant costs. Assembling clips, adding text overlays (e.g., “Safety Zone”), and transitions in DaVinci Resolve takes 20 to 50 hours, costing AED 2,000 to AED 15,000. Incorporating quizzes or clickable hotspots for training platforms adds 10 to 30 hours, costing AED 1,000 to AED 9,000. Client feedback, such as adjusting camera angles, can add 10 to 20 hours, costing AED 1,000 to AED 6,000. A UAE manufacturer required interactive quizzes for a 3D factory plant walkthrough project, increasing editing costs. Underestimating this phase can delay delivery and affect quality.

Distribution and Platform Optimization

Ensuring 3D factory plant walkthrough projects are compatible with websites, VR, or mobile platforms requires optimization. Optimizing for VR (e.g., Oculus) or mobile devices adds 10 to 20 hours, costing AED 1,000 to AED 6,000. Hosting on secure platforms like Vimeo Pro costs AED 1,000 to AED 3,000 per year. Testing across iPhones or VR headsets requires 5 to 10 hours, costing AED 500 to AED 3,000. A Dubai industrial park needed VR optimization for a 3D factory plant walkthrough project, adding costs. Poor optimization reduces accessibility, limiting the project’s reach.

Project Management and Coordination

Managing a 3D factory plant walkthrough project involves coordinating artists, engineers, and clients, often leading to unforeseen costs. Project management tools like Trello or Asana cost AED 500 to AED 2,000 per year. Multiple client meetings add travel or virtual meeting costs of AED 1,000 to AED 5,000. Scope creep or miscommunication can extend timelines, increasing labor costs by AED 5,000 to AED 20,000. A UAE factory project required extra meetings, inflating costs. Poor coordination risks budget overruns and missed deadlines.

Maintenance and Updates

Keeping 3D factory plant walkthrough projects relevant requires ongoing updates for new equipment, layouts, or regulations. Revising animations for new machinery or ADNOC regulations takes 20 to 50 hours, costing AED 2,000 to AED 15,000. Storing master files in ProRes requires cloud storage, costing AED 500 to AED 2,000 per year. Integrating worker feedback adds 10 to 20 hours, costing AED 1,000 to AED 6,000. A 3D factory plant walkthrough project for an ADNOC refinery needed annual updates for HSE protocols, adding costs. Neglecting updates can render walkthroughs obsolete.

Strategies to Manage Hidden Costs

To mitigate the hidden costs of 3D factory plant walkthrough projects, UAE businesses can adopt practical strategies:

-

Develop a comprehensive project scope with timelines, assets, and compliance requirements to avoid scope creep. Chasing Illusions Studio excels at outlining ADNOC-specific needs upfront.

-

Use free tools like Blender to reduce software costs compared to Autodesk Maya (AED 7,000/year).

-

Design modular assets for easy updates, as practiced by Chasing Illusions Studio.

-

Train staff in 3D animation using Blender Guru or CG Cookie to reduce consultant costs.

-

Allocate a 10–20% budget buffer for revisions or compliance reviews.

-

Partner with experts like Chasing Illusions Studio, praised for “stunning explainer videos” (Elena Martinez), for efficient production.

-

Render low-resolution previews to catch errors before high-resolution rendering.

-

Budget for multilingual narration upfront to avoid last-minute audio costs.

Tools and Resources

To create cost-effective 3D factory plant walkthrough projects:

-

Animation Software: Blender (free), Autodesk Maya (AED 7,000–15,000/year), Unreal Engine (VR rendering).

-

Editing Software: DaVinci Resolve (free), Adobe Premiere Pro (AED 1,000–3,000/year).

-

Audio: Freesound.org (sound effects), YouTube Audio Library (music).

-

Tutorials: Blender Guru, CG Cookie, Udemy for 3D animation training.

-

Communities: Reddit’s r/3Dmodeling, Blender Artists for feedback.

-

UAE Resources: ADNOC HSE guidelines, UAE Ministry of Economy for compliance.

Best Practices for 3D Factory Plant Walkthrough Projects

To maximize the value of 3D factory plant walkthrough projects:

-

Ensure clear visuals for key areas like safety zones or equipment.

-

Align with ADNOC HSE, OSHA, and NFPA 56 standards.

-

Use storytelling and interactive elements, as shown by Chasing Illusions Studio.

-

Include Arabic, English, and Hindi for UAE’s workforce.

-

Pilot walkthroughs with workers or clients for accuracy.

-

Design for web, VR, and mobile to maximize ROI.

Challenges and Solutions

Creating 3D factory plant walkthrough projects presents challenges:

-

High production costs: Use Blender and modular designs.

-

Regulatory complexity: Consult ADNOC HSE experts early, as done by Chasing Illusions Studio.

-

Language barriers: Budget for multilingual narration.

-

Rendering times: Optimize models and use cloud rendering sparingly.

3D factory plant walkthrough projects are vital for UAE businesses, enhancing training, marketing, and planning in oil and gas and manufacturing. Hidden costs like planning, modeling, compliance, and updates can inflate budgets, but strategic management and partnerships with Chasing Illusions Studio (chasingillusions.com) can ensure success. As the UAE’s industrial sector grows in 2025, mastering these costs will maximize the impact of 3D factory plant walkthrough projects.